We also offer

What Is Layer of Protection Analysis (LOPA)?

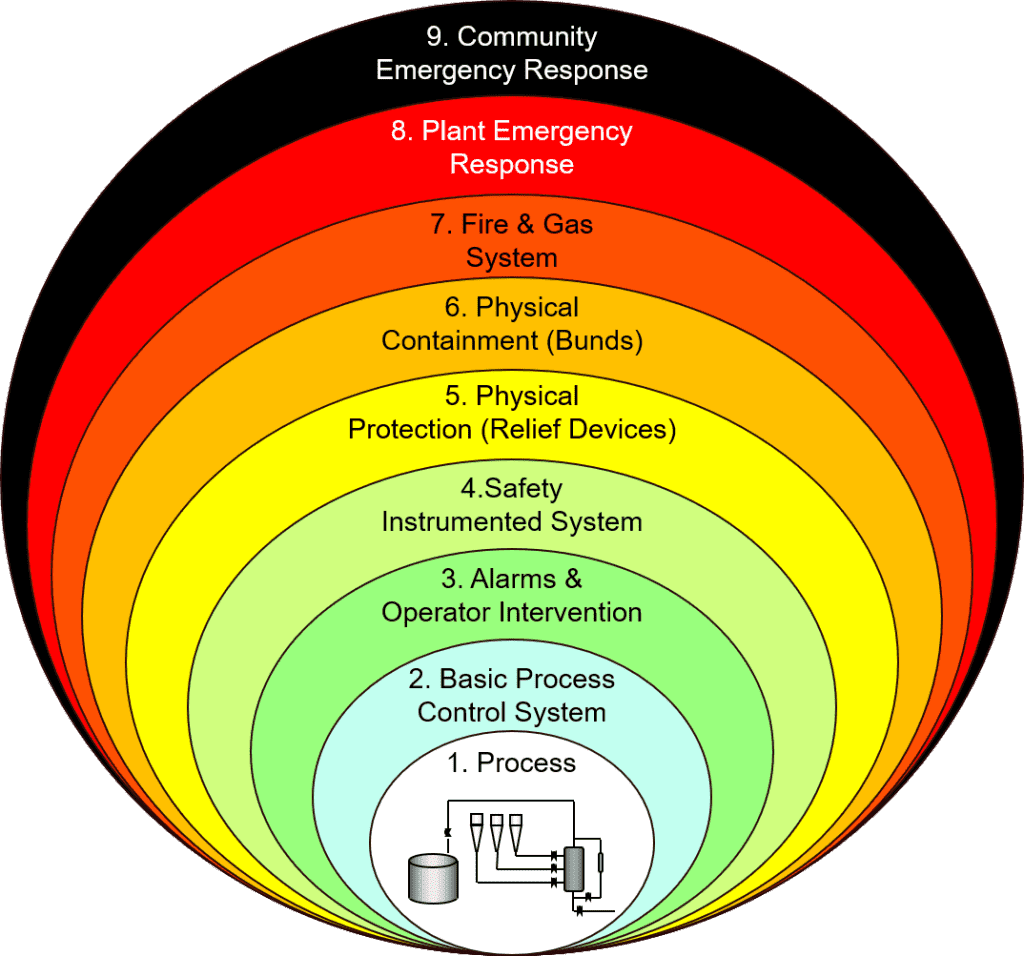

Layer of Protection Analysis (LOPA) is a semi-quantitative risk assessment method used in the process industry to evaluate and manage risks in hazardous operations. LOPA helps determine whether existing safety measures (called independent protection layers or IPLs) are sufficient or if additional layers are required to reduce the risk of accidents such as explosions, fires, or toxic releases.

It is widely used in industries such as chemical processing, oil and gas, pharmaceuticals, and other high-risk sectors. By analyzing specific incident scenarios, LOPA helps quantify the likelihood of a hazardous event and the effectiveness of safeguards, contributing to smarter, risk-based decision-making in process safety management (PSM).

How Does a Layer of Protection Analysis (LOPA) Study Work?

A LOPA study breaks down a hazardous scenario into key components:

-

Initiating Events – What could trigger the hazardous scenario (e.g., equipment failure, operator error)?

-

Consequences – What happens if the initiating event occurs?

-

Protection Layers – What safeguards exist to prevent or mitigate the outcome?

-

Risk Quantification – What’s the likelihood of failure, and is the risk level acceptable?

For example, if high pressure in a reactor could cause a rupture, a LOPA study would assess the probability of that pressure increase, the effectiveness of relief valves or alarms, and whether additional controls are necessary.

Why Is Layer of Protection Analysis (LOPA) Important?

Performing a Layer of Protection Analysis is critical to:

-

Identify and quantify process safety risks

-

Ensure existing safeguards are effective

-

Justify the need for additional controls or systems

-

Comply with regulatory standards like OSHA PSM, EPA RMP, and IEC 61511

-

Set appropriate Safety Integrity Levels (SIL) for Safety Instrumented Systems (SIS)

-

Make informed, cost-effective safety investment decisions

LOPA bridges the gap between qualitative assessments like HAZOP and complex quantitative models, offering a balanced, structured approach to improving operational safety.

Key Steps in the Layer of Protection Analysis (LOPA) Methodology

1. Define the Scope

Select high-risk scenarios from previous HAZOP studies or incident reviews.

2. Identify Initiating Events

Determine how each scenario could start, and estimate the frequency.

3. Analyze Consequences

Assess the severity of possible outcomes if no protection existed.

4. List Existing IPLs

Identify safeguards like alarms, SIS, pressure relief devices, or operator actions.

5. Evaluate Risk

Calculate the risk level considering the initiating event and IPL effectiveness.

6. Recommend Additional Safeguards

If risk is too high, propose new IPLs or system changes to reduce it.

7. Document and Report

Prepare a complete LOPA report including all scenarios, assumptions, and recommendations.

8. Implement and Track

Develop an action plan with responsibilities, deadlines, and follow-up tracking.

9. Review and Update

Revisit the LOPA as processes, technologies, or regulations change.

10. Communicate and Train

Share results and ensure all stakeholders understand their role in maintaining safety.

Why Perform a Layer of Protection Analysis (LOPA) Study?

Conducting a LOPA study offers key benefits:

-

Improves safety through layered risk reduction

-

Quantifies risk for better safety investment decisions

-

Supports SIL determination for critical safety systems

-

Enhances regulatory compliance with OSHA, EPA, and global safety standards

-

Reduces downtime and incidents by proactively managing risks

LOPA is an essential part of any comprehensive process safety program, helping organizations prioritize safety actions and allocate resources efficiently.

Why Choose Prime Process Safety Center

At Prime Process Safety Center, we bring proven expertise and deep industry knowledge to every LOPA study.

What Sets Us Apart:

-

Experienced Facilitators – Experts in LOPA, HAZOP, SIL, and PHA methodologies

-

Tailored Risk Assessments – Customized for your facility’s specific operations and hazards

-

Actionable Recommendations – Practical, implementable safety improvements

-

Regulatory Compliance Support – Meet OSHA, EPA, and IEC requirements

-

Quantitative Risk Expertise – Accurate risk calculation for high-stakes decisions

-

Comprehensive Reports – Clear documentation with traceable analysis and findings

-

Training and Knowledge Transfer – Upskill your team in LOPA principles and practices

-

Ongoing Support – Help with implementation, follow-ups, and future revalidations

FAQ

1. What is Layer of Protection Analysis (LOPA)?

LOPA is a risk management tool used to assess and reduce process safety risks by evaluating the effectiveness of existing protective layers and identifying the need for additional safety measures.

2. Why is LOPA important in process safety?

LOPA helps in understanding the likelihood of hazardous events and the effectiveness of safety systems, providing a structured approach to making safety-related decisions and ensuring compliance with industry standards.

3. How does LOPA differ from other risk assessment methods?

LOPA provides a semi-quantitative middle ground between qualitative methods like HAZOP and more complex quantitative risk assessments, offering detailed yet understandable risk insights.

4. What are ‘layers of protection’ in LOPA?

Layers of protection refer to the various safety barriers, controls, and systems in place to prevent or mitigate the consequences of hazardous events, such as alarms, interlocks, and emergency response procedures.

5. When should a LOPA study be conducted?

A LOPA study is typically conducted after a preliminary hazard analysis, like a HAZOP, when further detailed risk evaluation is needed to make informed safety decisions.

6. Who should perform a LOPA study?

LOPA studies should be conducted by professionals with expertise in process safety, risk analysis, and the specific operations of the facility.

7. What is involved in a LOPA study?

A LOPA study involves identifying potential hazardous scenarios, determining the likelihood of these scenarios, evaluating existing protective layers, and recommending additional safety measures if needed.

8. How do you determine the effectiveness of safety layers in LOPA?

The effectiveness is evaluated based on factors like reliability, independence, and auditability of each layer against the specific hazard scenarios.

9. What outcomes can be expected from a LOPA study?

Outcomes include a better understanding of risk levels, identification of areas where safety can be improved, and actionable recommendations for enhancing process safety.

10. How does LOPA contribute to regulatory compliance?

By systematically assessing and managing risks, LOPA helps ensure compliance with safety regulations and standards, reducing the likelihood of accidents and potential liabilities.