The inherent risks associated with combustible dust have been a longstanding concern across various industries. From manufacturing to agriculture, the potential for combustible dust explosions poses a significant threat to worker safety and facility integrity. Understanding the nuanced factors that contribute to the explosibility of combustible dust properties is paramount for effective risk management and mitigation strategies. In this comprehensive blog post, we delve into the multifaceted nature of combustible dust properties and their influence on explosibility. These properties include the following:

- Chemical Composition

- Particle Shape

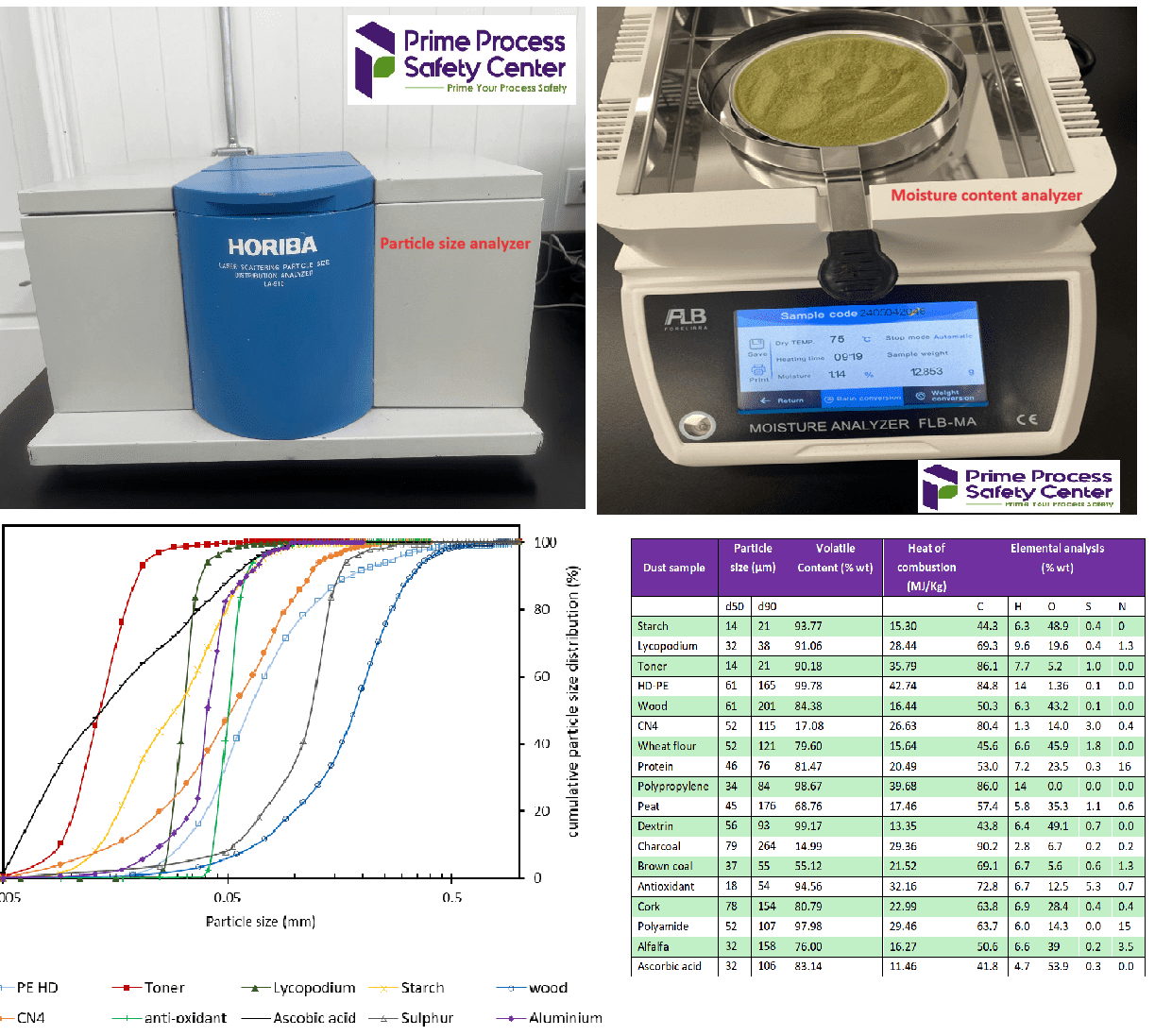

- Particle Size Distribution

- Moisture Content

- Thermal Stability

- Surface Area and Porosity

- Combustion Characteristics

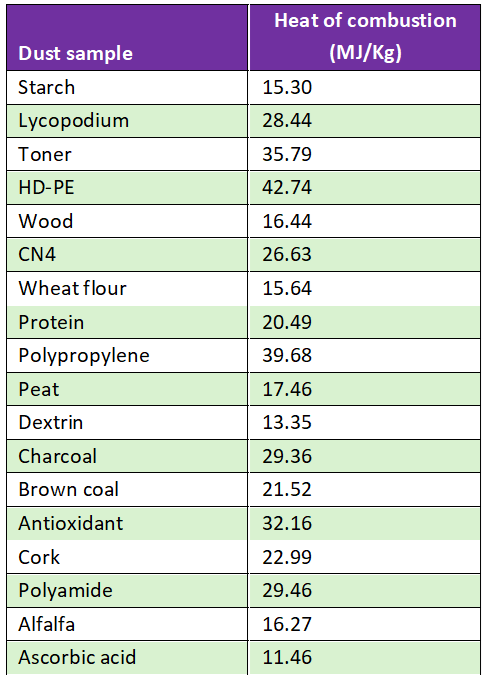

- Heat of Combustion

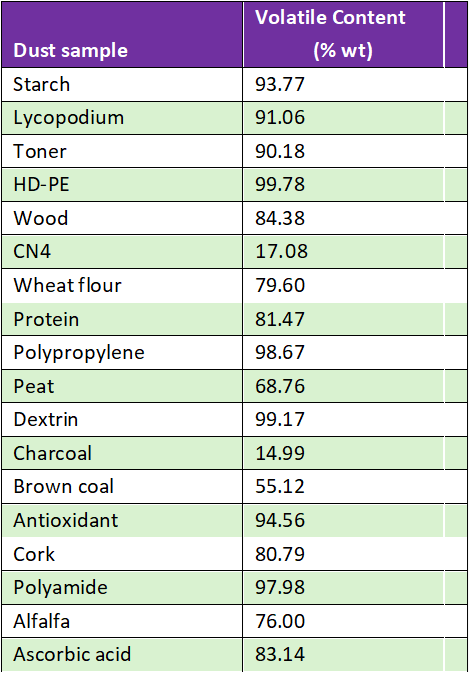

- Volatile Content

- Initial temperature

- Effect of Initial Pressure

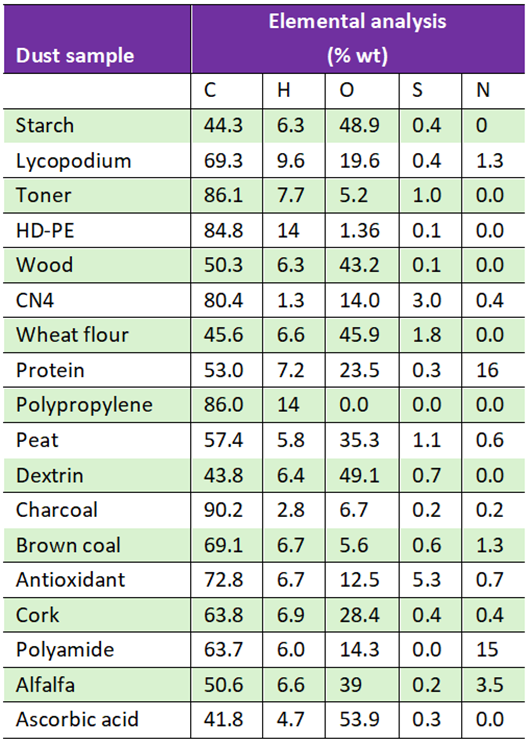

Chemical Composition

The combustible nature of dust hinges significantly on its chemical composition, with certain compounds exhibiting heightened reactivity and combustion potential, thereby increasing susceptibility to ignition and explosion. Oxygen-rich functional groups, volatile substances, and reactive elements exacerbate explosibility, necessitating thorough chemical analysis for accurate risk assessment. Elements such as carbon, hydrogen, sulfur, and other flammable compounds within the dust profoundly impact its propensity to combust, while Particle Size Analysis and surface area, influenced by chemical composition, play pivotal roles in facilitating rapid combustion and the formation of explosive dust clouds. Chemical reactions with air or other substances further contribute to heat generation and explosion potential, with additives, impurities, or contaminants also influencing reactivity. Understanding these factors is imperative for effectively assessing and mitigating risks associated with combustible dust handling, processing, and storage, thereby averting catastrophic explosions and ensuring personnel and property safety.

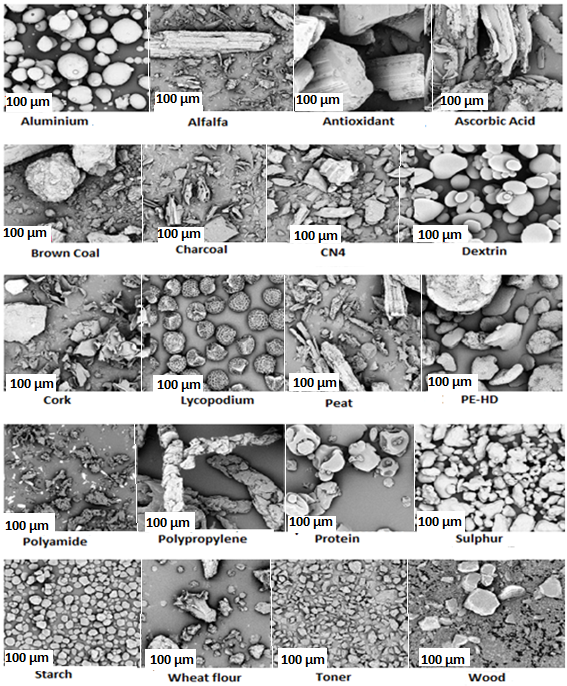

Particle Shape

Particle shape plays a pivotal role in the behavior and severity of dust explosions, with irregularly shaped particles having higher surface area-to-volume ratios than spherical ones, thus promoting more efficient combustion and potentially leading to more intense explosions due to rapid flame propagation within the dust cloud. Additionally, irregular shapes affect aerosolization, as irregularly shaped particles tend to agglomerate, reducing dispersibility, while spherical particles disperse more uniformly, forming homogenous dust clouds that are easier to ignite and sustain combustion. Furthermore, irregular shapes impact packing density, resulting in looser packing and higher porosity within dust layers or piles, increasing the likelihood of dust cloud formation and enhancing explosibility. Understanding these effects is crucial for assessing and mitigating the risks associated with dust handling, processing, and storage, necessitating careful consideration of particle shape and its influence on explosibility, combustion characteristics, and dust cloud behavior during explosion events.

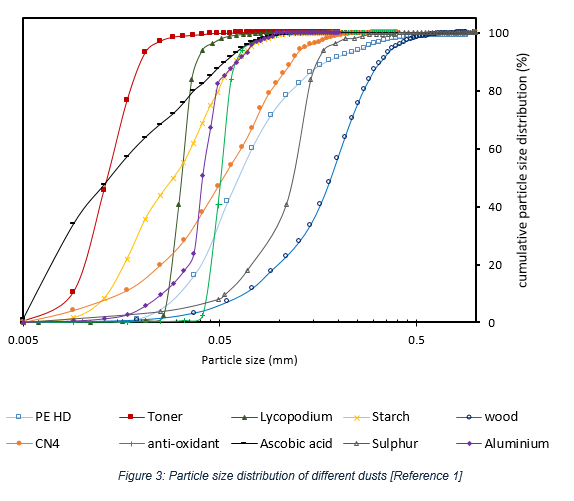

Particle Size Distribution

Particle size profoundly influences the characteristics and severity of dust explosions, with finer particles facilitating more efficient combustion and faster flame propagation within dust clouds, thus accelerating ignition and potentially leading to more intense explosions. Moreover, smaller particles form aerosols that disperse rapidly, creating combustible dust clouds with heightened concentrations of combustible material, further escalating explosion severity. Additionally, particle size distribution significantly impacts the Minimum Explosible Concentration (MEC)/Lower Explosible Limit (LEL), with finer particles generally exhibiting lower MEC values, rendering dust composed of smaller particles more susceptible to explosion hazards. Furthermore, particle size affects packing density and porosity, with finer particles packing more densely and potentially trapping air pockets, increasing dust accumulation explosibility. Understanding these size-related effects is crucial for assessing and mitigating the risks associated with dust handling, processing, and storage, demanding careful consideration of particle size and its impact on explosibility, combustion characteristics, and dust cloud behavior during explosion events.

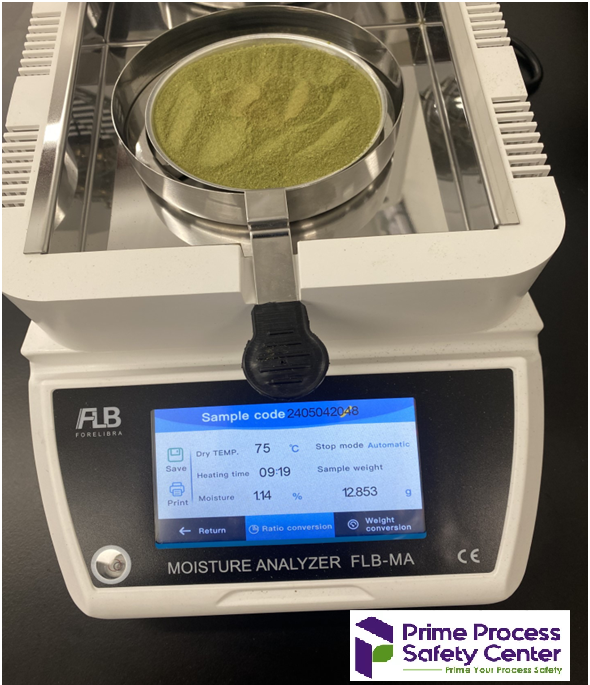

Moisture Content

The moisture content of combustible dust is a critical determinant of the likelihood and severity of dust explosions. Higher moisture levels can impede combustible dust cloud formation by causing particle agglomeration, limiting suspension in air, and reducing combustible material availability for ignition, thereby mitigating explosibility. However, excessive moisture may paradoxically enhance ignition sensitivity, either by acting as a heat-absorbing barrier or facilitating conductive path formation within the dust, increasing ignition risk in the presence of a spark. Moreover, moisture significantly influences combustion characteristics, with higher levels decreasing heat release rates and acting as diluents, reducing combustible material concentration and explosibility. Understanding these effects is vital for assessing and mitigating risks associated with dust handling, necessitating appropriate preventive measures like moisture control and dust management strategies to minimize dust explosion potential and ensure personnel and facility safety.

Flammable Volatile Content

The volatile content of combustible dust significantly influences the likelihood and severity of dust explosions by providing additional fuel. Higher volatile content increases the risk of dust ignition, as volatile compounds can vaporize readily and ignite at lower temperatures, leading to more frequent and severe dust explosions, particularly in environments with ignition sources. Additionally, volatile compounds contribute to faster flame propagation within dust clouds, fueling more rapid flame spread and resulting in larger affected areas and more intense explosions. Moreover, volatile content directly impacts the energy released during combustion, influencing the magnitude and destructive force of a dust explosion. Dust with higher volatile content has the potential to produce more powerful explosions, posing greater risks to personnel and equipment. Understanding these effects is crucial for assessing explosion hazards and implementing preventive measures to mitigate risks effectively. Controlling volatile content, alongside factors like dust concentration and environmental conditions, is essential for minimizing the potential for dust explosions and ensuring the safety of personnel and facilities handling combustible dust materials. By comprehensively addressing volatile content and its impact on ignition sensitivity, flame propagation, and explosion energy, organizations can enhance safety protocols and reduce the likelihood of catastrophic dust explosions.

Thermal Stability

The thermal stability of combustible dust materials significantly influences the occurrence and severity of dust explosions. Lower thermal stability can lead to lower ignition temperatures, increasing susceptibility to ignition in environments with heat sources like sparks or hot surfaces, necessitating stringent safety measures to mitigate explosion risks. Moreover, thermal stability affects the rate of heat release during combustion, with higher-stability materials releasing heat more gradually, potentially reducing combustion intensity and mitigating explosion severity. Conversely, lower thermal stability may result in more rapid heat release, leading to forceful explosions posing greater risks to personnel and infrastructure. Additionally, thermal stability influences flame propagation within dust clouds, with lower stability fostering faster flame spread, amplifying destructive potential and hazards associated with dust handling and storage. Understanding this relationship is crucial for industrial risk management. Implementing measures to control ignition sources and regulate dust accumulation can significantly reduce the likelihood and impact of dust explosions, ensuring personnel and facility safety. Comprehensive evaluation of thermal stability using techniques like Differential Scanning Calorimeter (DSC) or Thermogravimetric Analysis (TGA) is essential for assessing potential explosibility and enhancing safety protocols.

Surface Area and Porosity

The surface area and porosity of combustible dust particles are pivotal factors in determining the characteristics and severity of dust explosions. Finer particles, with larger surface area-to-volume ratios, facilitate faster and more efficient combustion by providing numerous ignition sites, potentially leading to more intense explosions with higher pressures and temperatures. Additionally, increased surface area enhances dust cloud formation, heightening the explosibility of the dust and exacerbating explosion hazards. Porosity influences the ability of dust particles to form compacted layers or piles, with highly porous particles potentially trapping air within their structures, facilitating dust cloud formation and explosion propagation. Moreover, porous particles exhibit increased moisture absorbency, which can alter the dust’s ignition sensitivity and combustion characteristics. Understanding these effects is crucial for effectively assessing and mitigating associated risks in handling, processing, and storing combustible dust materials. Implementing preventive measures, such as controlling dust dispersion and managing dust accumulations, is essential to minimize the potential for dust explosions and ensure personnel and facility safety.

Combustion Characteristics

The combustion characteristics of combustible dust materials are fundamental in determining the occurrence and severity of dust explosions, encompassing factors that dictate ignition, burning, and flame spread during explosion events. One crucial aspect is the heat release rate, directly impacting explosion intensity and severity. Materials with higher heat release rates tend to generate more intense explosions, resulting in greater pressure rises and temperatures within the explosion zone. Assessing the heat release rate is essential for identifying explosion hazards and implementing preventive measures effectively. Moreover, combustion characteristics significantly influence flame propagation speed and extent within a dust cloud. Some materials support rapid flame spread, leading to extensive combustion and more severe explosions with larger affected areas and greater potential for damage. Additionally, explosion energy, determined by the energy released during combustion, shapes the magnitude and destructive force of a dust explosion. A comprehensive understanding of combustion characteristics, including factors like heat release rate and flame propagation, is essential for assessing explosion risks and implementing preventive measures to minimize the potential for dust explosions effectively.

Heat of Combustion

The heat of combustion plays a pivotal role in the dynamics of combustible dust explosions, significantly impacting their intensity and consequences. These explosions occur when a cloud of fine combustible particles encounters an ignition source, triggering rapid combustion and energy release. Higher heats of combustion result in more energy available for the explosion, leading to a sudden escalation of pressure and temperature within the confined space, potentially causing severe damage to surrounding areas and infrastructure. Moreover, the heat of combustion influences the speed and extent of flame propagation through the dust cloud. Dust particles with elevated heat of combustion emit more heat energy, accelerating flame propagation rates and causing more rapid flame spread, resulting in larger affected areas and exacerbating the explosion’s impact. Additionally, higher heats of combustion increase the ignition sensitivity of dust clouds, heightening the likelihood of explosion occurrence in the presence of ignition sources such as sparks or flames. Managing the heat of combustion is crucial for assessing and mitigating the risks associated with combustible dust materials, as it directly impacts explosion intensity, flame propagation, and ignition sensitivity, thereby reducing the potential for catastrophic explosions and ensuring the safety of personnel and facilities handling such materials.

Initial Temperature

The initial temperature of the environment surrounding combustible dust is crucial in determining the likelihood and severity of dust explosions. Higher initial temperatures increase the risk of spontaneous ignition or ignition by external heat sources like hot surfaces or sparks, heightening the overall risk of dust explosions, particularly in environments with prevalent ignition sources or significant heat generation. Additionally, elevated initial temperatures accelerate combustion rates, leading to faster flame propagation and more intense explosions. Furthermore, these higher temperatures may alter the thermal decomposition behavior of dust particles, potentially impacting the energy release rate and overall severity of the explosion. Moreover, elevated initial temperatures contribute to higher pressure and temperature rises during a dust explosion event. As combustible dust ignites and combusts, the release of heat energy results in rapid pressure and temperature increases within the confined space of the explosion. Higher initial temperatures exacerbate these effects, leading to more significant pressure waves and higher temperatures, posing greater risks to personnel and equipment in the vicinity of the explosion. Understanding the effects of initial temperature on ignition sensitivity, combustion characteristics, and explosion dynamics is crucial for assessing explosion hazards and implementing preventive measures to mitigate risks effectively. Measures such as controlling ambient temperatures, isolating ignition sources, and implementing dust control measures are vital steps to minimize the potential for dust explosions and ensure the safety of personnel and facilities handling combustible dust materials.Top of Form

Effect of Initial Pressure

The initial pressure of the environment surrounding combustible dust significantly influences the occurrence and severity of dust explosions. Elevated initial pressures can lead to more significant pressure rises during a dust explosion event, exacerbating the effects of heat release and potentially causing greater damage to surrounding equipment and structures. Moreover, initial pressure conditions impact various aspects of explosion dynamics, including flame propagation and the extent of explosion propagation. Higher initial pressures can accelerate flame speed and intensity, resulting in more rapid flame spread and larger affected areas during an explosion, while also influencing the behavior of shock waves generated by the explosion and affecting the distribution of damage and hazards within the surrounding environment. Understanding the effects of initial pressure on dust explosions is crucial for effectively assessing explosion hazards and implementing preventive measures to mitigate risks. Controlling initial pressure conditions, alongside other factors such as temperature and dust concentration, is essential for minimizing the potential for dust explosions and ensuring the safety of personnel and facilities handling combustible dust materials. By comprehensively considering the impact of initial pressure on explosion dynamics, organizations can enhance their safety protocols and mitigate the potential for catastrophic events.

Conclusion

The explosibility of combustible dust properties is governed by a complex interplay of chemical composition, particle characteristics, moisture content, thermal stability, electrostatic properties, and combustion behavior. By comprehensively understanding these factors and their interactions, industrial facilities can implement targeted risk management measures to minimize the likelihood and consequences of dust explosions. Effective dust explosion prevention requires a multidisciplinary approach that integrates material science, process engineering, and safety management to safeguard personnel, equipment, and infrastructure from catastrophic events. Prime Process Safety Center offers the following combustible dust testing services; Go/No Go Explosibility Screening, Burn Rate/Fire Train Test, Dangerous When Wet Test, Dust Explosion Severity (Kst/Pmax/dP/dt), Minimum Explosible Concentration (MEC)/Lower Explosible Limit (LEL), Limiting Oxygen Concentration (LOC) Test, Minimum Ignition Energy (MIE), Minimum Autoignition Temperature-Cloud (MAIT–Cloud) and Layer Ignition Temperature of Dust (LIT).

References

Addai, E. K. (2016). Investigation of Explosion Characteristics of Multiphase Fuel Mixtures with Air. Germany: Western Engineering, Incorporated.