We also offer

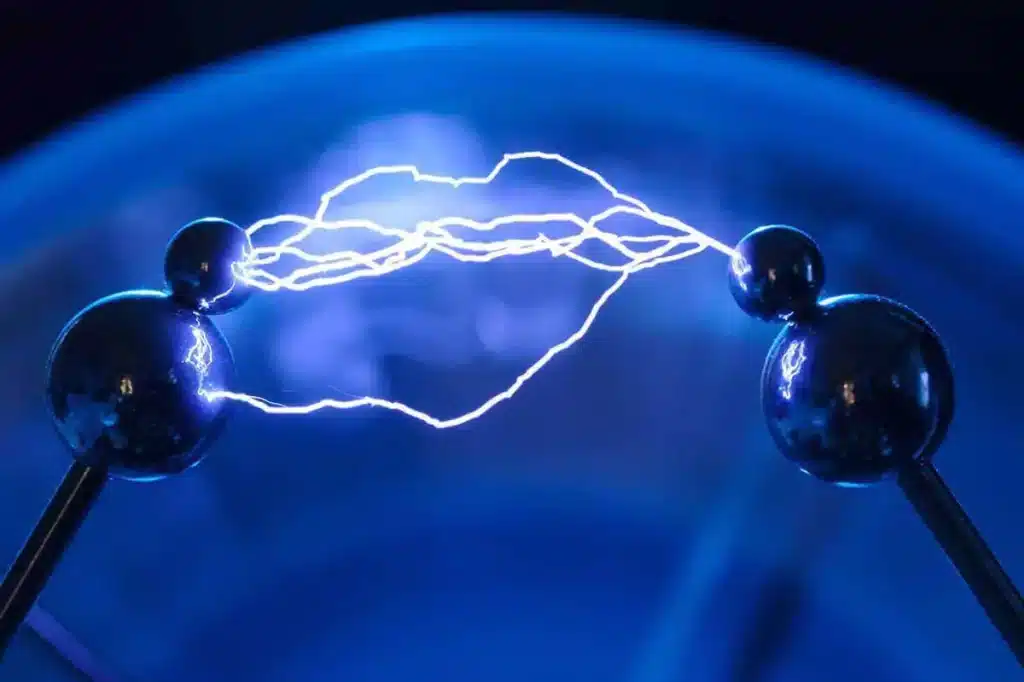

What is Electrostatic Chargeability

Electrostatic chargeability is a property of materials that enables them to acquire electric charge through friction, induction, or conduction without current flow. When electrons transfer between objects, one material gains a net negative charge while the other becomes positively charged. This process explains static electricity phenomena like lightning, charged object attraction, and devices such as photocopiers and electrostatic precipitators.

Understanding electrostatic chargeability is essential for designing materials, developing technologies, and ensuring safety in environments where static buildup can disrupt electronics or cause hazards.

Testing Principle and Methodology

For solid materials, the test involves subjecting samples to triboelectrification or constant rubbing with materials from the triboelectric series for several minutes. The accumulated charge is then measured with a static field meter.

For powders, the test measures charge generated by contact charging (triboelectrification) against materials like glass or plastic. Powder flows through a test pipe via a vibratory feeder while a vacuum pulls it through, causing powder-to-pipe contact. Collected powder accumulates charge measured by an electrometer connected to a Faraday cup. Chargeability is calculated as charge per powder mass. Testing repeats with different pipe materials and at two humidity levels (ambient and low %RH).

Applicable Standard

Testing follows ASTM D4470-97, Standard Test Method for Static Electrification.

Data Interpretation

Materials with high electrostatic chargeability require safety measures to reduce static risks. Proper grounding of materials and equipment prevents charge buildup by connecting conductive parts to earth. Bonding equalizes electrical potential between conductive items, reducing discharge risk. Using anti-static materials that dissipate charge and maintaining higher humidity levels also help minimize static accumulation.

Installing ionizers or static eliminators can neutralize static charges in areas with high chargeability materials, improving safety and operational reliability.

When to Perform Electrostatic Chargeability Testing

Testing is recommended for industries and applications where static buildup poses risks or affects processes, such as handling flammable substances, operating in explosive atmospheres, or working with sensitive electronics. It’s vital during material development or selection to identify static charge propensity, enabling safer material choices.

Routine chargeability testing as part of preventive maintenance supports ongoing monitoring and risk reduction.

Why Choose Prime Process Safety Center

Prime Process Safety Center leads in process safety testing with highly experienced laboratory personnel. Our goal is to deliver accurate, reliable, and defensible data that complies with industry and regulatory standards. We understand the critical need for high-quality data and work diligently to achieve it.

- As an ISO/IEC 17025:2017 accredited laboratory, we follow rigorous quality and competency requirements for every test we perform.

-

We have extensive expertise in electrostatic chargeability testing for both powders and solid materials, ensuring dependable results.

-

Our state-of-the-art testing equipment provides precise and sensitive measurements.

-

We adhere to strict protocols and quality control measures to maintain consistent test outcomes.

-

Our team offers detailed data interpretation and practical recommendations tailored to your specific application or research needs.

Partnering with Prime Process Safety Center means you receive trustworthy insights to manage electrostatic risks effectively and improve safety in your operations.

FAQ

What causes static electricity?

Static electricity is caused by the movement or transfer of electrons between materials. When two materials come into contact and then separate, electrons can be transferred, leaving one material positively charged (having lost electrons) and the other negatively charged (having gained electrons).

How does static electricity affect electronics?

Static electricity can damage electronic components. When a static discharge occurs, it can generate a high voltage that may exceed the tolerance of sensitive electronic parts, leading to their failure or malfunction.

Which materials are more prone to static charge buildup?

Materials that are poor conductors of electricity (insulators) are more prone to accumulating static charges. Examples include plastics, rubber, glass, and certain fabrics like synthetic fibers.

What are the dangers associated with static discharge?

Static discharge can lead to hazardous situations, such as fires or explosions in environments where flammable gases, vapors, or dust are present. It can also cause damage to electronic devices, disrupt manufacturing processes, or ignite combustible materials.

How can static electricity be controlled or minimized?

- Static electricity can be controlled through various means:

- Grounding and bonding systems to dissipate charges.

- Using anti-static materials that allow charges to dissipate more readily.

- Managing humidity levels to reduce static buildup.

- Implementing static eliminators or ionizers in areas prone to static accumulation.

- Educating personnel on proper handling techniques to minimize friction and charge buildup.