We also offer

Expert Burn Rate & Fire Train Testing Services

A non-explosible material is not necessarily non-combustible. Many substances can burn vigorously and still pose serious hazards in processing environments. The burn rate (fire train) test, often performed as part of combustible dust testing, helps determine how a material burns and whether it falls into a regulated packing group based on its combustibility.

This test plays a vital role in safety assessments and regulatory compliance—especially in industries such as aerospace, pyrotechnics, ammunition manufacturing, and material handling, where precise knowledge of combustion behavior is essential.

Testing Principle and Methodology

Standard procedures recommend testing the material as received, in its commercial form. If you’re unsure how to prepare your sample, contact Prime Process Safety Center for guidance. Most tests use 100 grams of material.

Here’s how the burn rate/fire train test works:

-

The technician forms the sample into an unbroken strip or powder train.

-

During screening, they attempt ignition using a hot flame (≥1000°C).

-

If ignition occurs, the lab proceeds to a full burn rate test.

For the full test:

-

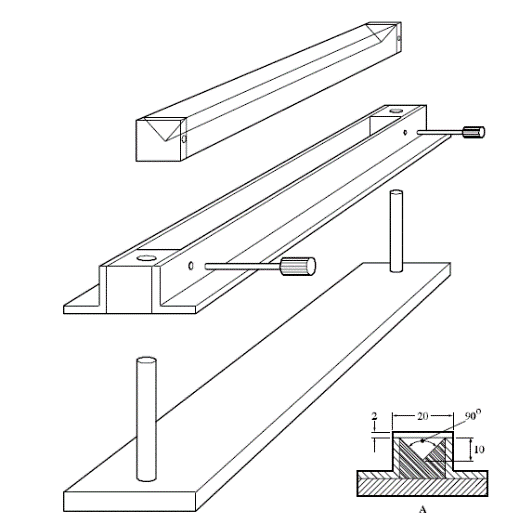

The material is shaped into a strip about 250 mm long × 20 mm wide × 10 mm high, placed on a nonporous, cool, heat-resistant base plate.

-

A flame is applied to one end for up to 2 minutes (for organic materials) or 5 minutes (for metals or metal alloys).

-

The lab observes whether the material ignites or smolders and whether it propagates the flame.

Applicable Standards

Burn rate and fire train testing at Prime Process Safety Center follows established regulatory and technical guidelines to ensure reliable and compliant results. We conduct testing in accordance with:

-

UN/DOT Section 33 – Classification Procedures, Test Methods, and Criteria relating to Class 4 materials, which outlines how to identify and categorize flammable solids (Division 4.1).

-

VDI 2263 – Dust Fire and Explosion Protection, a German technical guideline that provides methods for testing the fire behavior of dusts and solid materials.

These standards ensure consistency in classifying the combustibility of materials and determining their appropriate packing group for transportation and safety planning.

Data Interpretation

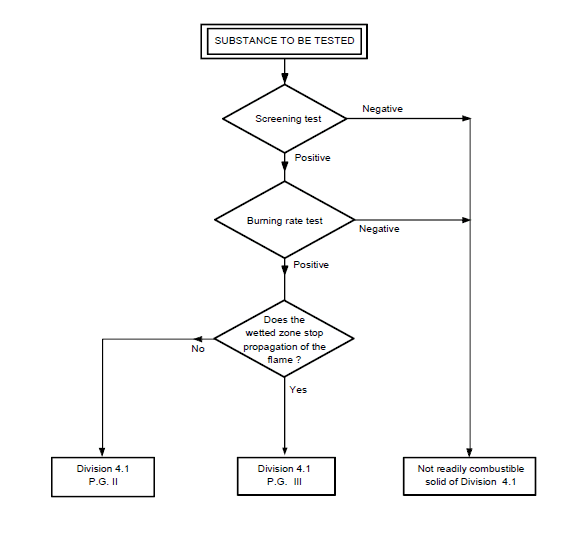

The test determines whether the material falls under Division 4.1 of the hazardous materials classification system:

-

If the material does not ignite, smolder, or propagate flame to the 200 mm mark within the allowed time (2 or 5 minutes), it is not classified as Division 4.1.

-

If the material does ignite or smolder and the flame reaches the 200 mm mark within the test period, the material qualifies as Division 4.1 and must undergo the full burn rate test to determine its appropriate packing group.

Burn rate testing helps:

-

Classify materials for safe transportation

-

Mitigate flash fire hazards caused by hot embers or frictional heat

-

Assess risks associated with propellants, pyrotechnics, explosives, and energetic materials

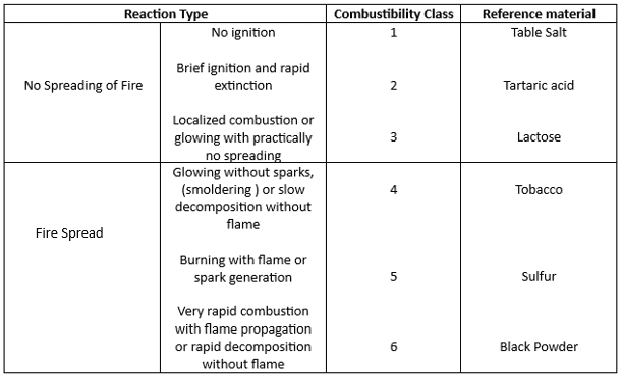

The test also supports combustibility classification based on the material’s reaction type, following regulatory charts and standards.

When to Perform the Burn Rate / Fire Train Test

If a material is non-explosible (No-Go), it may still be combustible. In such cases, Prime Process Safety Center recommends performing the burn rate test to assess fire behavior and ensure safety.

Industries should conduct burn rate testing during:

-

Product development

-

Manufacturing and production

-

Process modifications

-

Routine safety checks

This testing supports compliance, improves material safety, and helps prevent combustion-related incidents in high-risk industries.

Why Choose Prime Process Safety Center

Prime Process Safety Center brings deep expertise and a commitment to high-quality testing as an ISO/IEC 17025:2017 accredited laboratory. Here’s what sets us apart:

-

Experienced personnel with extensive knowledge in dust combustibility testing

-

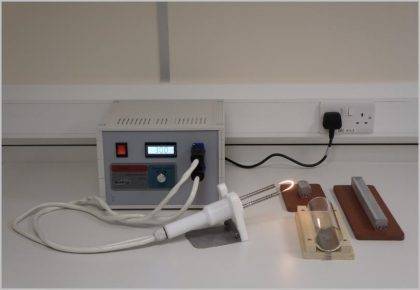

Advanced equipment for precise and sensitive burn rate measurements

-

Strict testing protocols that ensure repeatable and defensible results

-

Clear data interpretation and insight tailored to your material or process

Our team works diligently to deliver accurate results that meet regulatory and industry standards—so you can move forward with confidence.

FAQ

What is the burn rate in the context of combustible materials?

Burn rate refers to the speed at which a substance, typically a solid propellant or explosive material, burns or undergoes combustion under controlled conditions. It is a critical parameter that defines the rate of energy release during combustion.

Why is burn rate testing important for combustible materials?

Burn rate testing is crucial as it provides essential data regarding how fast a material burns or combusts. This information is vital for assessing performance, safety, and reliability in applications such as rocket propulsion, ammunition, pyrotechnics, and other industries dealing with energetic materials.

How is burn rate testing performed for combustible materials?

Burn rate testing involves subjecting a sample of the material to controlled conditions, typically within a test chamber, where its combustion is observed and measured. The test measures the rate at which the material burns or undergoes combustion under specific parameters.

What factors influence the burn rate of combustible materials?

Several factors can influence the burn rate of combustible materials, including the composition of the material, particle size, shape, density, pressure, temperature, and the presence of additives or stabilizers.

How is burn rate data utilized in practical applications?

Burn rate data obtained from testing is crucial for designing and developing propellants, explosives, and energetic materials. This data assists in optimizing formulations, predicting performance under various conditions, ensuring safety, and meeting regulatory compliance.