We also offer

What is Air Over Layer / Powder Layer Test

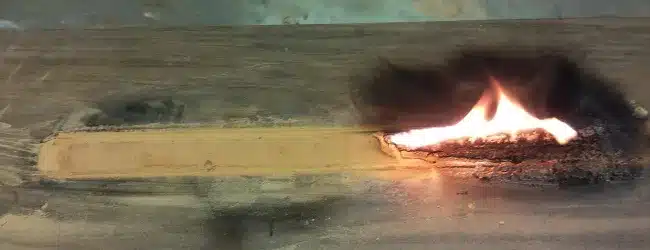

The Air Over Layer/Powder Layer Test assesses the ignition properties and flammability of combustible dust layers exposed to an air stream. This test helps identify fire and explosion risks related to dust deposits in industrial environments. It simulates hot air passing over dust layers, such as in cross flows, trays, band dryers, or deposits on dryer surfaces.

Testing Principle and Methodology

A metal tray is filled with about a 15mm layer of the test sample. Hot air flows around the tray, heating the powder layer. K-type thermocouples monitor both the powder and oven temperatures. Oven temperature controls the air temperature.

During the screening test, the oven temperature rises at 0.5°C per minute until it reaches 400°C. The isothermal test then uses the onset self-heating temperature from the screening test and is repeated at various steady temperatures. This test runs between 8 and 24 hours, with accuracy maintained between 2°C and 10°C.

Applicable Standard

The powder layer test follows the procedure described by John Abbot in Preventing Fires and Explosions in Dryers.

Data Interpretation

A safety margin of 20°C is generally recommended to reduce the risk of material decomposition, but it should not be the sole safety measure. This test determines the ignition temperature of a 15mm thick powder layer, typical of deposits in many plants. For deeper layers, ignition temperatures decrease, so deeper layer tests may be required. More information about depth effects is available in the Self-Heating Evaluation and Analysis under Reactive Chemical Services.

When to Perform Powder Layer Test

This test simulates dryer conditions where hot air circulates over material layers or settled deposits on internal surfaces. It provides crucial information for setting operating conditions that prevent exothermic reactions in powder layers.

Why Choose Prime Process Safety Center

Prime Process Safety Center leads in process safety testing with highly experienced lab personnel. We deliver accurate, reliable, and defensible data meeting industry and regulatory standards. Our team understands the importance of quality data and works diligently to provide it.

As an ISO/IEC 17025:2017 accredited laboratory, we follow rigorous quality and competency requirements for every test we perform. We have expert knowledge in powder layer testing to ensure precise, reliable results. Our advanced powder layer testing equipment offers sensitive and accurate measurements. Strict protocols and quality control guarantee consistent results. We also interpret test data, offering insights and recommendations tailored to your needs.

FAQ

What is the Air Over Layer Test for combustible dust?

Answer: The Air Over Layer Test assesses the flammability and ignition properties of a layer of combustible dust when exposed to an airflow and a heated environment.

Why is the Air Over Layer Test conducted?

Answer: It is conducted to evaluate how combustible dust layers interact with hot airflow and in a heated environment, helping in assessing fire and explosion risks in industrial settings.

How is the Air Over Layer Test performed?

Answer: A layer of combustible dust is spread on a surface of a metal tray within a test apparatus, and controlled airflow is directed over this layer while observing the self-heating behaviors of the sample.

What types of materials are commonly tested using the Air Over Layer Test?

Answer: Various types of combustible dust, including powders, granules, or fine particles from different industries like woodworking, food processing, or chemical manufacturing, are tested using this method.

What parameters are monitored during the Air Over Layer Test?

Answer: Parameters such as ignition time, flame propagation, combustion behavior, and potential for explosion are observed and recorded during the test.

How does the test simulate real-world scenarios involving combustible dust layers and airflow?

Answer: The test replicates conditions where dust layers are exposed to airflow, such as through ventilation systems, by subjecting them to controlled air streams within the test setup.

How are the test results utilized in industrial settings?

Answer: The data obtained helps in evaluating fire risks associated with combustible dust layers, guiding risk assessment, preventive measures, and safety protocols in workplaces.