We also offer

What is Cryogenic Grinding?

In the realm of particle size reduction and material processing, cryogenic grinding offers a powerful solution—especially for materials sensitive to heat or requiring precise particle size control. This technique uses ultra-low temperatures to preserve material properties while producing fine, uniform particles and improving product quality.

Testing Principle and Methodology

Cryogenic grinding uses cryogenic temperatures—typically below -80°C (-112°F)—to embrittle materials before grinding. The process begins with pre-cooling the material, often using liquid nitrogen, which makes the material more brittle and easier to fracture.

We use liquid nitrogen as the refrigerant in the pre-cooling unit to bring the material to the required low temperature. Once cooled, the material is ground using a specialized cryogenic mill designed to operate efficiently under these conditions.

The brittleness at low temperatures allows for finer and more consistent particle size reduction. This precision is especially important in industries like pharmaceuticals, food, and polymers, where particle uniformity can directly affect performance and quality.

Why Cryogenic Grinding Is Used

Cryogenic grinding is used when conventional size-reduction methods generate excessive heat, cause material degradation, or produce inconsistent particle characteristics. By operating at ultra-low temperatures—typically with liquid nitrogen—the process preserves heat-sensitive materials while enabling efficient particle size reduction.

Under ambient grinding conditions, temperature rise can result in:

-

Melting or softening of polymers and elastomers

-

Smearing or agglomeration of ductile materials

-

Loss of volatile components

-

Thermal degradation of active ingredients

-

Oxidation or chemical instability

When to Perform Cryogenic Grinding

Cryogenic grinding is an ideal method when:

-

Materials are sensitive to heat and may degrade or lose properties at higher temperatures.

-

Fine and uniform particle size is critical to the end application.

-

Product quality and integrity must be preserved during the grinding process.

Its ability to produce consistent, high-quality results makes it a preferred method across many industries.

Why Choose Prime Process Safety Center

Prime Process Safety Center is a trusted leader in process safety testing, backed by an ISO/IEC 17025:2017 accredited laboratory, experienced laboratory personnel and a strong commitment to quality.

-

We have extensive knowledge and hands-on experience in cryogenic grinding, ensuring accurate and reliable results.

-

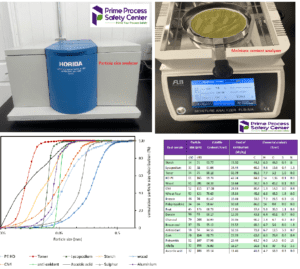

Our facility features state-of-the-art cryogenic grinding equipment, capable of delivering precise, sensitive measurements.

-

We follow strict testing protocols and quality control measures to ensure consistent, defensible outcomes.

-

Our team can analyze and interpret test data, offering insights and recommendations tailored to your application or research needs.

At Prime Process Safety Center, we work diligently to provide dependable data that meets both industry and regulatory standards.

FAQ

What is cryogenic grinding, and how does it work?

Answer: Cryogenic grinding is a method of particle size reduction that involves grinding materials at ultra-low temperatures, typically below -80°C (-112°F), using liquid nitrogen or other cryogenic gases. The process begins by pre-cooling the material to render it brittle, facilitating easier grinding. The cold and brittle state enables finer and more uniform particle size reduction compared to conventional grinding methods.

What materials are suitable for cryogenic grinding?

Answer: Cryogenic grinding is ideal for heat-sensitive and soft materials such as spices, herbs, plastics, pharmaceuticals, food products, and polymers. These materials often experience degradation or altered properties when processed at higher temperatures, making cryogenic grinding an optimal choice to preserve their integrity.

What are the advantages of cryogenic grinding over conventional grinding methods?

Answer: Cryogenic grinding offers several advantages, including, preservation of material properties, maintaining the integrity of heat-sensitive or volatile substances, enhancing particle size control, producing finer and more uniform particle sizes, reducing risk of contamination: Minimizes the chance of contamination due to the closed, controlled environment of the process.

What equipment is required for cryogenic grinding?

Answer: The essential equipment includes a pre-cooling unit, which uses liquid nitrogen or cryogenic gases to cool the material, and a specialized grinding mill capable of operating at ultra-low temperatures. This grinding mill is designed to handle the brittle state of the pre-cooled material and achieve fine particle size reduction.

What are the key applications of cryogenic grinding?

Answer: Cryogenic grinding finds applications across various industries:

- Pharmaceuticals: Processing heat-sensitive pharmaceutical ingredients while maintaining their potency.

- Food industry: Grinding spices, herbs, and food products without compromising taste or nutritional value.

- Plastics and polymers: Producing fine polymer powders for various plastic products without altering their properties.