We also offer

Flammability Limit Test

The flammability limit test is conducted to determine the lower and upper flammable concentration limits of chemicals that have sufficient vapor pressure to form flammable mixtures at atmospheric pressures and specific temperatures. This test is typically performed on volatile liquids and gaseous materials such as refrigerants.

The Lower Explosive Limit (LEL) or Lower Flammable Limit (LFL) is the minimum concentration of a combustible substance that can propagate a flame in a homogeneous mixture of the combustible material and air under the specified test conditions.

The Upper Explosive Limit (UEL) or Upper Flammable Limit (UFL) is the maximum concentration of a combustible substance that can propagate a flame under the same specified test conditions.

Understanding these limits is critical for ensuring the safe handling, storage, and processing of flammable gases and vapors.

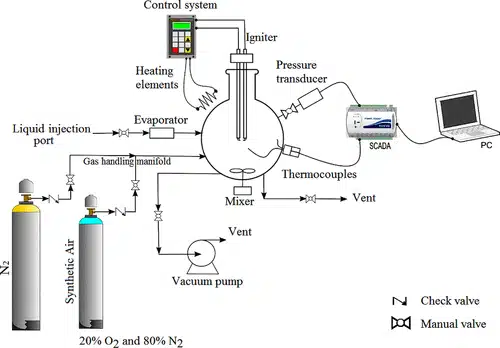

Testing Principle and Methodology

Determination of the Lower Flammable Limit (LFL)

Generally, 1% v/v of the material is added to a glass vessel under a vacuum. Air is then allowed back into the system, and the material and air are mixed before an electrical source of ignition is activated. Observations are made for flame propagation away from the ignition source.

The material concentration is subsequently increased in 1% increments until ignition is observed, defining the Lower Explosive Limit (LEL).

Determination of the Upper Flammable Limit (UFL)

Once the LEL has been established, a theoretical Upper Explosive Limit is calculated. Testing then begins at a concentration above the theoretical UEL.

The material is added to a glass vessel under a vacuum, air is allowed back into the system, and the mixture is ignited using an electrical source. Observations for flame propagation are made, and the material concentration is decreased in 1% steps until ignition is observed—defining the Upper Explosive Limit (UEL).

Applicable Standard

Refrigerant gases are tested to ASHRAE 34 using the method detailed within ASTM E681 – Standard Test Method for Concentration Limits, with specific ignition criteria and air moisture content requirements.

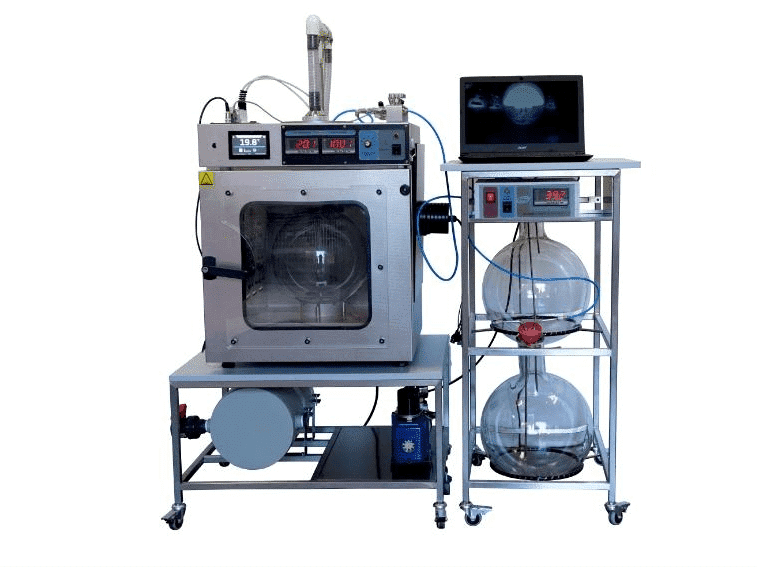

Concentration limits and flammability of refrigerants determination equipment are manufactured by Anko, providing reliable performance for accurate LFL/UFL determination.

Concentration limits and flammability of refrigerants determination equipment manufactured by Anko

Data Interpretation

The flammability limits depend on the test temperature and pressure. This test method is limited to an initial pressure of the local ambient or less, with a practical lower pressure limit of approximately 13 kPa (100 mm Hg). The maximum practical operating temperature of the equipment is approximately 150°C.

The limits of flammability determined from the test can be used to develop guidelines for the safe handling of volatile chemicals. These results are particularly useful for assessing ventilation requirements in areas where gases and vapors are present.

Understanding the flammability range helps facilities implement appropriate safety controls, minimize explosion hazards, and maintain regulatory compliance when working with flammable or combustible substances.

When to Perform LFL/UFL Testing

Lower Flammable Limit (LFL) and Upper Flammable Limit (UFL) tests for gases and volatile liquids should be performed under specific circumstances to ensure safety, compliance, and risk mitigation.

LFL and UFL tests are commonly conducted during the development of new materials or formulations to understand the flammability characteristics of substances being manufactured or handled.

The tests are also recommended:

-

After incidents involving flammable substances, to analyze causes and develop preventive measures.

-

When environmental conditions (such as temperature or pressure) change, as these may alter flammability characteristics.

-

Following any modification in chemical composition or formulation, since small variations can affect the flammability limits.

Re-evaluating the LFL and UFL under such circumstances ensures continued process safety and regulatory compliance.

Why Choose Prime Process Safety Center

Prime Process Safety Center is a leader in process safety testing, staffed by highly experienced laboratory personnel dedicated to delivering accurate, reliable, and defensible data that meet industry and regulatory standards.

At Prime Process Safety Center:

-

We are knowledgeable and experienced in performing lower and upper flammable limit tests, ensuring accurate and repeatable results.

-

Our state-of-the-art testing equipment provides precise and sensitive measurements for both LFL and UFL testing.

-

We follow strict testing protocols and quality control measures to ensure consistency and reliability.

- We follow rigorous quality and competency requirements for every test we perform.

-

Our experts can interpret and analyze test data, providing valuable insights and recommendations tailored to your specific application or research.

Our goal is to provide trusted flammability limit testing services that support your safety programs, research, and product development needs.

FAQ

What are Lower Flammable Limit (LFL) and Upper Flammable Limit (UFL)?

Answer: LFL refers to the minimum concentration of a gas or vapor in air below which the mixture is too lean to ignite. UFL indicates the maximum concentration above which the mixture is too rich to ignite.

Why are LFL and UFL Important in Assessing Flammability?

Answer: Understanding LFL and UFL is crucial for safety as it defines the range of concentrations where gases or vapors can ignite. Operating within this range minimizes fire or explosion risks.

How Are LFL and UFL Determined for Gases and Vapors?

Answer: These limits are determined through laboratory testing using specialized equipment to identify the concentrations at which ignition occurs. Methods include using flame arrestors or ignition sources in controlled environments.

What Factors Affect LFL and UFL of Gases and Vapors?

Answer: Factors such as temperature, pressure, composition, and presence of inert gases impact the flammability limits. Changes in these variables alter the LFL and UFL of substances.

What Are the Safety Implications of Knowing LFL and UFL?

Answer: Understanding these limits helps in establishing safe operating conditions, designing ventilation systems, and implementing safety measures to prevent ignitable atmospheres that could lead to fires or explosions.