We also offer

What Is a Limiting Oxygen Concentration(LOC) Test?

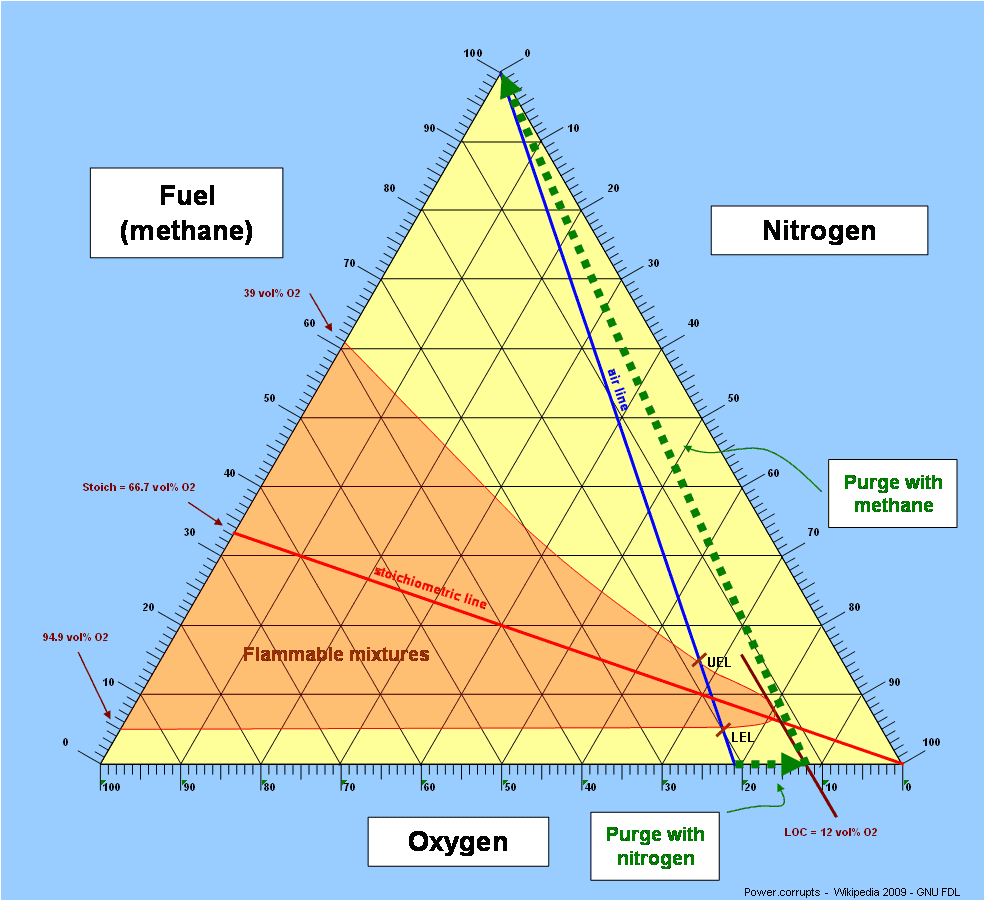

The Limiting Oxygen Concentration (LOC) for combustible dust is the minimum oxygen level in air at which a dust explosion or combustion cannot be sustained, even with an ignition source or sufficient fuel. It defines the lower boundary below which a dust-air mixture cannot support combustion or explosion.

Testing Principle and Methodology

- A sample of the dust is dispersed in a 20L Sphere, which is pressurized with a compressed air–inert air mixture using partial pressures.

- A 2.5 kJ chemical ignitor is activated to attempt ignition.

- ASTM recommends the sample have a particle size of at least 95% less than 75 microns and moisture content below 5%.

In some unique cases where the material does not segregate during normal operation, we test the sample as received. If you’re unsure how to prepare your sample, contact Prime Process Safety Center for guidance.

To determine the LOC, we vary the oxygen concentration around the dust’s most easily ignitable concentration (typically based on the Kst/Pmax value). We gradually replace oxygen with nitrogen to reduce flammability. The LOC is reached when the pressure ratio in the chamber drops below 2.0.

Typical Dust Explosion Graph for LOC determination in a 20L Sphere

Applicable Standard

The LOC test follows ASTM E2931, Standard Test Method for Limiting Oxygen (Oxidant) Concentration of Combustible Dust Clouds, and BS EN 14034 Part 4.

Data Interpretation

Testers determine the LOC based on the pressure ratio in the chamber. If the pressure ratio reaches 2.0 or higher, or if Pmax exceeds 0.5 barG, the test confirms ignition. The lowest oxygen level that no longer supports ignition defines the LOC.

Engineers use LOC test results to design nitrogen inerting systems that maintain safe oxygen levels during processing. Understanding the LOC is crucial for:

- Fire and Explosion Prevention

- Risk Assessment and Hazard Analysis

- Safety Protocol Development

- Process and Equipment Design

- Regulatory Compliance

- Incident Prevention and Worker Safety

- Emergency Preparedness

When Do You Perform A Limiting Oxygen Concentration(LOC) Test?

LOC testing is essential in settings where flammable materials, including combustible dusts, are present. It is particularly important when inerting is used to prevent explosions. LOC testing should also be performed during:

- New material introductions

- Regulatory compliance checks

- Incident reviews

Regular LOC assessments help ensure workplace safety and prevent dust-related fire or explosion hazards.

Why Choose Prime Process Safety Center

Prime Process Safety Center is a trusted leader in process safety testing with experienced laboratory personnel. Our mission is to provide accurate, reliable, and defensible data that meets both industry and regulatory standards.

- Our team is highly experienced in conducting LOC tests.

- We use advanced explosibility testing equipment to ensure precision.

- Strict protocols and quality control ensure consistent results.

- We interpret your test results and provide meaningful recommendations for your application or research.

As an ISO/IEC 17025:2017 accredited laboratory, we follow rigorous quality and competency requirements for every test we perform.

FAQ

What is the Limiting Oxygen Concentration (LOC) of combustible dust?

Answer: The LOC refers to the minimum oxygen concentration in the air below which a dust explosion or combustion involving combustible dust cannot be sustained, even in the presence of an ignition source or sufficient fuel.

Why is understanding the Limiting Oxygen Concentration (LOC) important in industries dealing with combustible dust?

Answer: Knowledge of the LOC is critical for assessing fire and explosion risks associated with combustible dust. It assists in establishing safe oxygen concentration limits, preventing dust-related incidents, and ensuring workplace safety.

How is the Limiting Oxygen Concentration (LOC) determined for combustible dust?

Answer: LOC assessments involve testing methods that gradually reduce the oxygen concentration in controlled environments while observing the ability of combustible dust to sustain combustion or support an explosion.

What factors influence the Limiting Oxygen Concentration (LOC) of combustible dust?

Answer: Factors such as the type of dust, particle size distribution, moisture content, chemical composition, and specific characteristics of the dust significantly impact the LOC for combustible dust.

How is knowledge of the Limiting Oxygen Concentration (LOC) utilized in workplace safety and prevention of dust-related incidents?

Answer: Understanding the LOC assists in developing safety protocols, inerting systems, compliance with safety regulations, incident prevention, emergency preparedness, and ensuring safe handling practices concerning oxygen concentrations in workplaces dealing with combustible dust.