We also offer

What Is a Minimum Explosible Concentration (MEC) Test?

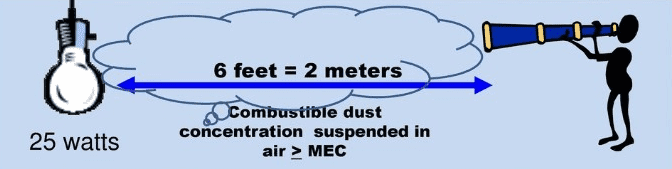

The Minimum Explosible Concentration (MEC) test determines the lowest concentration of a dust-air mixture that can propagate a deflagration in a closed system such as a 20L Sphere. It identifies the minimum amount of combustible dust in air capable of producing an explosion if ignited. This value represents the lower limit at which the dust-air mixture can sustain combustion or explosion and is a core part of combustible dust testing.

The MEC is a critical threshold: below this concentration, the mixture is too lean (below the Lower Explosive Limit, LEL) to support sustained combustion or explosion. Once the concentration exceeds the MEC, the mixture can sustain combustion if ignited.

Testing Principle and Methodology

-

Typically, about 100 g/m³ of the test material is dispersed in a 20L Sphere chamber pressurized with compressed air.

-

A 2.5 kJ chemical ignitor is activated to attempt ignition.

-

ASTM recommends the dust particle size be at least 95% smaller than 75 microns and contain less than 5% moisture.

-

In special cases where no material segregation occurs during normal operation, testers may use the sample as received.

-

If unsure how to prepare your sample, contact Prime Process Safety Center for guidance.

Testing steps:

-

If ignition occurs during the first trial (pressure ratio ≥ 2.0), decrease concentration until the pressure ratio falls below 2.0.

-

If no ignition occurs initially, increase concentration in 100 g/m³ increments until ignition is observed.

-

The difference between ignition and non-ignition concentrations must not exceed 25%, as recommended by ASTM.

Applicable Standards

The MEC test is performed in accordance with the following standards:

-

ASTM E1515 – Standard Test Method for Minimum Explosible Concentration of Combustible Dusts

-

BS EN 14034 Part 3

These standards ensure consistency, accuracy, and regulatory compliance.

Data Interpretation

-

The MEC is determined by analyzing the pressure ratio generated inside the 20L Sphere during testing.

-

A pressure ratio of 2.0 or greater indicates ignition of the dust-air mixture.

-

Both ignition and non-ignition concentrations must be repeatable.

-

Testers establish the MEC as the highest dust concentration where ignition does not occur, just below the concentration where ignition reliably happens.

When to Perform a MEC Test?

MEC determination is important for assessing dust explosibility hazards in many scenarios, including:

-

Risk assessments and hazard analyses

-

Safety protocols and preventive measures

-

Process optimization and equipment design

-

Regulatory compliance training and awareness

-

Incident investigation and prevention

Why Choose Prime Process Safety Center

Prime Process Safety Center is a leader in process safety testing with highly experienced laboratory personnel. Our goal is to provide accurate, reliable, and defensible data that meets industry and regulatory standards.

-

We specialize in minimum explosible concentration and lower explosive limit testing, ensuring precise and trustworthy results.

-

Our state-of-the-art MEC/LEL testing equipment offers sensitive and accurate measurements.

-

We follow strict testing protocols and quality control to guarantee consistent results.

-

Our expert team interprets and analyzes data to provide valuable insights and recommendations tailored to your specific application or research needs.

- As an ISO/IEC 17025:2017 accredited laboratory, we ensure every test meets the highest standards of competence, impartiality, and technical rigor.

FAQ

What is the Minimum Explosible Concentration (MEC) of combustible dust?

Answer: The MEC represents the lowest concentration of combustible dust in the air that is capable of sustaining a dust explosion if ignited. It serves as a critical threshold below which the dust-air mixture is too lean to support combustion or explosion.

Why is determining the MEC of combustible dust important?

Answer: Determining the MEC is crucial as it helps in assessing the explosibility hazards associated with combustible dust. This information is used for risk assessment, implementing safety measures, designing processes, and ensuring compliance with safety regulations.

How is the Minimum Explosible Concentration (MEC) determined for different dust types?

Answer: The MEC is determined through various testing methods that involve creating dust-air mixtures with varying concentrations. These tests measure the lowest concentration at which the dust-air mixture is capable of sustaining an explosion under controlled conditions.

What factors influence the MEC of combustible dust?

Answer: Several factors influence the MEC, including the particle size distribution, moisture content, chemical composition, and dust characteristics such as reactivity, shape, and surface area. These factors impact the dust's explosibility.

How is the knowledge of MEC utilized in industry or workplace settings?

Answer: Understanding the MEC is utilized in industries dealing with combustible dust for risk mitigation, process optimization, equipment design, worker safety training, regulatory compliance, and incident prevention to ensure safe handling and management of combustible dust.