We also offer

What Is Particle Sieve Analysis?

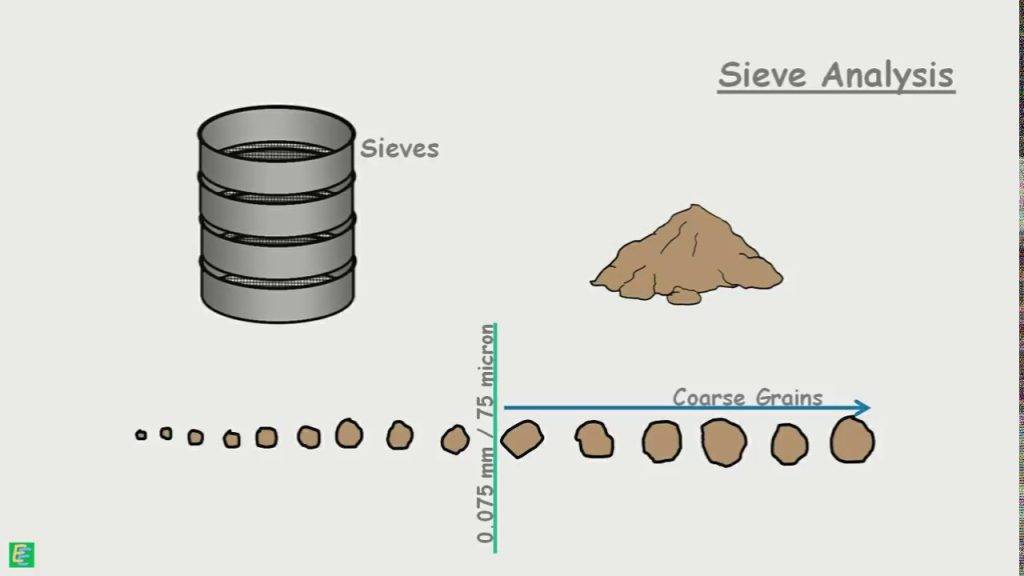

Particle sieve analysis is a technique used to determine the distribution of particle sizes in a granular material. It involves separating particles using a series of sieves with progressively smaller openings. This method is commonly used before combustibility testing, since a material’s explosibility often depends on its particle size distribution.

Why Particle Sieve Analysis Is Important

Particle sieve analysis determines the particle size distribution of powders and bulk solids, which directly affects material performance and safety.

Accurate particle size data is essential to:

-

Verify product quality and batch consistency

-

Evaluate flowability, blending, and handling characteristics

-

Support milling and size-reduction optimization

-

Assess combustible dust hazards, particularly the fraction of fine particles

-

Meet quality control and regulatory requirements

In combustible dust applications, the proportion of fine particles can significantly influence explosibility and reactivity. Reliable sieve analysis provides the data necessary for engineering decisions, process optimization, and hazard evaluation.

When to Perform Particle Sieve Analysis

Particle sieve analysis is widely used across industries such as construction, agriculture, pharmaceuticals, and mining. It characterizes the particle sizes of materials like aggregates, soils, powders, sands, and other granular substances.

The technique supports:

-

Quality control

-

Material classification

-

Selection of appropriate materials for specific applications based on particle size distribution

Testing Principle and Methodology

ASTM E11 describes the procedure for determining the particle size distribution of materials ranging from coarse aggregates to fine powders. The method involves the following steps:

-

Sieve Preparation: Arrange a stack of sieves in order of decreasing aperture size. Weigh each sieve and record the weight.

-

Sample Preparation: Collect the test sample in a way that accurately represents the entire bulk material.

-

Sieving Process: Place the prepared sample on the top sieve. Shake the stack—either manually or with a mechanical shaker—for about 10 minutes. Smaller particles fall through to lower sieves, while larger ones remain above.

-

Post-Processing: After shaking, collect and weigh the material on each sieve. Calculate the percentage of material retained on each sieve relative to the total sample weight.

-

Size Distribution Curve: Use the data to plot a particle size distribution curve, showing the proportion of particles in each size range.

Applicable Standard

The standard method for sieve analysis is defined in ASTM E11, which outlines procedures for determining particle size distribution in granular materials.

Data Interpretation

The sieve analysis results are typically presented in tables or graphs to show the particle size distribution. This data helps evaluate the material’s uniformity and grading.

These results also guide decisions on whether to test a sample for explosibility as received or prepare it further—such as by sieving or grinding—before testing.

How to Conduct Particle Sieve Analysis

Particle sieve analysis is performed using a calibrated stack of standard test sieves arranged in descending mesh size. A representative sample is placed on the top sieve and subjected to mechanical shaking or vibration for a specified duration.

The procedure typically includes:

-

Sample Preparation – Obtain a representative, dry sample to prevent agglomeration or bias.

-

Sieve Stack Assembly – Arrange sieves from largest to smallest opening, with a collection pan at the bottom.

-

Mechanical Agitation – Secure the stack in a sieve shaker and operate for a defined time to ensure consistent separation.

-

Mass Determination – Weigh the material retained on each sieve.

-

Data Calculation – Calculate the percentage retained and cumulative percentage passing to determine particle size distribution.

Results are reported in accordance with applicable standards (e.g., ASTM methods) and may be presented as tabulated data or particle size distribution curves.

Why Choose Prime Process Safety Center

Prime Process Safety Center is a leader in process safety testing with a team of experienced laboratory personnel.

- We have an ISO/IEC 17025:2017 accredited laboratory, we ensure every test meets the highest standards of competence, impartiality, and technical rigor.

-

We provide accurate, reliable, and defensible data that meets both industry and regulatory standards.

-

We are experienced in performing particle sieve analysis and delivering dependable results.

-

Our state-of-the-art equipment ensures precise and sensitive measurements.

-

We follow strict testing protocols and quality control procedures.

-

Our team offers data interpretation and insight, helping you understand the results and make informed decisions for your application or research.

FAQ

What is particle sieve analysis, and why is it important?

Particle sieve analysis is a method used to determine the particle size distribution of a granular material. It's crucial as it provides information about the range of particle sizes present in a sample, aiding in material characterization, quality control, and suitability for various applications.

How is particle sieve analysis conducted?

Particle sieve analysis involves using a series of sieves with different mesh sizes arranged in a stack from coarse to fine. A sample of the material is placed on the top sieve, and the stack is mechanically or manually shaken to separate particles based on size. The retained material on each sieve is then weighed and used to calculate the particle size distribution.

What types of materials can be analyzed using particle sieve analysis?

Particle sieve analysis is applicable to a wide range of materials, including soils, aggregates, sands, powders, granules, and other granular materials commonly used in industries like construction, agriculture, pharmaceuticals, and mining.

What are the limitations of particle sieve analysis?

While particle sieve analysis is a widely used method, it may not be suitable for materials with very fine particles or irregular shapes. Small particles may adhere to larger ones, affecting accuracy. Also, it does not provide information about particle shape or irregularities.

How are the results of particle sieve analysis interpreted and reported?

The results of the analysis are typically reported as a table or plotted on a graph showing the percentage of material retained on each sieve versus the sieve mesh size. This data helps visualize the particle size distribution and assists in understanding the material's characteristics.