We also offer

What is Thermogravimetric Analysis (TGA)?

Thermogravimetric Analysis (TGA) is a powerful technique used to study how materials change weight when heated under controlled conditions. The test is performed in either an inert or oxidizing atmosphere, offering insights into the composition, stability, and reactivity of a sample.

TGA applications include:

-

Measuring moisture and volatile content

-

Analyzing composition and material purity

-

Evaluating thermal and oxidative stability

-

Determining decomposition kinetics

Applicable Standards

Our Thermogravimetric Analysis (TGA) testing follows ASTM standards, ensuring reliable and recognized results:

-

ASTM E473 – Terminology Relating to Thermal Analysis

-

ASTM E1131 – Compositional Analysis by Thermogravimetry

-

ASTM E1582 – Calibration of Temperature Scale for Thermogravimetry

-

ASTM E1641 – Decomposition Kinetics by Thermogravimetry

-

ASTM E1868 – Loss-On-Drying by Thermogravimetry

-

ASTM E2008 – Volatility Rate by Thermogravimetry

-

ASTM E2040 – Mass Scale Calibration of Thermogravimetric Analyzers

-

ASTM E2105 – TGA Coupled With Infrared Analysis (TGA/IR)

-

ASTM E2403 – Sulfated Ash of Organic Materials by Thermogravimetry

-

ASTM E2550 – Thermal Stability by Thermogravimetry

-

ASTM D3850 – Rapid Thermal Degradation of Solid Electrical Insulating Materials by TGA

Principle of Operation

Thermogravimetric Analysis (TGA) measures both temperature and mass loss of a sample as it is heated in a specific environment. By monitoring these changes, the method reveals how the material behaves under increasing temperatures.

Test Method

-

Sample size: Typically 2–20 mg, depending on instrument setup.

-

Heating process: Temperature may be increased at a steady rate or adjusted to maintain constant mass loss.

-

Atmospheres: Tests can be performed in air, vacuum, inert gases, oxidizing/reducing gases, corrosive gases, carburizing gases, vapors, or self-generated atmospheres.

-

Pressure conditions: Options include high vacuum, high pressure, constant pressure, or controlled pressure environments.

Data Interpretation

TGA results are typically shown as a TGA curve, plotting sample mass (or percentage mass loss) against temperature or time. You can draw detailed insights from this curve:

-

TGA curve: Shows mass change relative to temperature or time.

-

DTG curve (first derivative): Highlights inflection points, useful for identifying specific transitions.

-

Differential analysis: Helps interpret decomposition stages, oxidation, or reactions.

With these tools, you can obtain:

-

Mass change vs. temperature

-

Mass change vs. time

-

Reactivity in air, oxygen, or other gases

-

Decomposition or reaction kinetics

Why Perform Thermogravimetric Analysis (TGA) Test?

Performing TGA in process safety provides critical information for preventing hazards. By tracking changes in mass as a material is heated, engineers can identify:

-

Thermal stability limits

-

Decomposition behavior under process conditions

-

Hazards such as ignition or toxic gas release

TGA also supports compatibility assessments and process optimization, helping reduce risks and improve safety measures. The insights from TGA testing guide safer process design, better material selection, and stronger protection for people, facilities, and the environment.

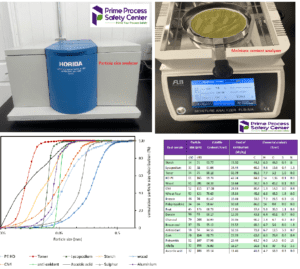

Why Choose Prime Process Safety Center

-

Expertise: Our team has deep experience in thermogravimetric analysis, ensuring accurate, reliable results.

-

Advanced equipment: We use state-of-the-art instruments for sensitive and precise measurements.

-

Quality control: Strict protocols ensure consistency and dependable outcomes.

-

Detailed reporting: We provide clear interpretations and recommendations tailored to your specific needs.

FAQ

1. What is Thermogravimetric Analysis (TGA)?

Thermogravimetric Analysis (TGA) is a technique used to measure the change in weight of a sample as it is subjected to a controlled temperature program. It provides information on the composition, thermal stability, and decomposition behavior of materials, making it valuable in process safety evaluations.

2. How does TGA work?

In TGA, a sample is heated in a controlled atmosphere while its weight change is continuously monitored. As the temperature increases, the sample may lose weight due to decomposition, evaporation, or other chemical reactions. The weight loss or gain is tracked over time, providing valuable information on the material's thermal behavior.

3. What are the applications of TGA in process safety?

TGA finds applications in process safety assessments by providing insights into the thermal stability and decomposition behavior of materials. It can help identify potential exothermic reactions, decomposition products, and the temperature range at which hazards can arise. TGA data aids in designing safe operating conditions and selecting appropriate mitigation strategies.

4. What type of information can be obtained from TGA measurements?

TGA measurements can provide valuable information, including:

- Identification of thermal stability and decomposition temperatures of materials.

- Quantification of weight loss or gain as a function of temperature or time.

- Assessment of the potential for hazardous gas evolution during heating.

5. Can TGA data be used for process optimization?

TGA data is primarily used for evaluating the thermal hazards of materials. However, the information obtained from TGA experiments, such as decomposition rates or temperature ranges, can be used to optimize process conditions to prevent undesired decomposition or reaction events. It helps in designing reactions or selecting materials that can withstand desired operating conditions while minimizing potential safety risks.