We also offer

What is a Vent Sizing Package (VSP) Test?

The Vent Sizing Package (VSP) was developed during the DIERS project in the 1980s. VSP plays a critical role in process safety by helping engineers determine the correct sizing for emergency relief systems (ERS) in industrial processes. Its low thermal inertia overcomes a common limitation of other equipment, which often underestimates self-heat rates and adiabatic temperature rise. This feature allows laboratory-scale runaway reactions to accurately mimic the severity of reactions in industrial vessels.

VSP is especially valuable for validating computerized runaway reaction models that incorporate kinetics, stoichiometry, heats of reaction, physical properties, and vapor-liquid equilibrium constants.

VSP applications include:

-

Distinguishing between homogeneous and non-foamy material behavior during emergency relief by measuring final void fraction.

-

Evaluating how viscosity affects homogeneous equilibrium flashing flow.

-

Determining parameters needed for ERS design using graphical or analytical methods.

-

Direct sizing of emergency relief devices through top- or bottom-vented experiments.

Principle of Operation

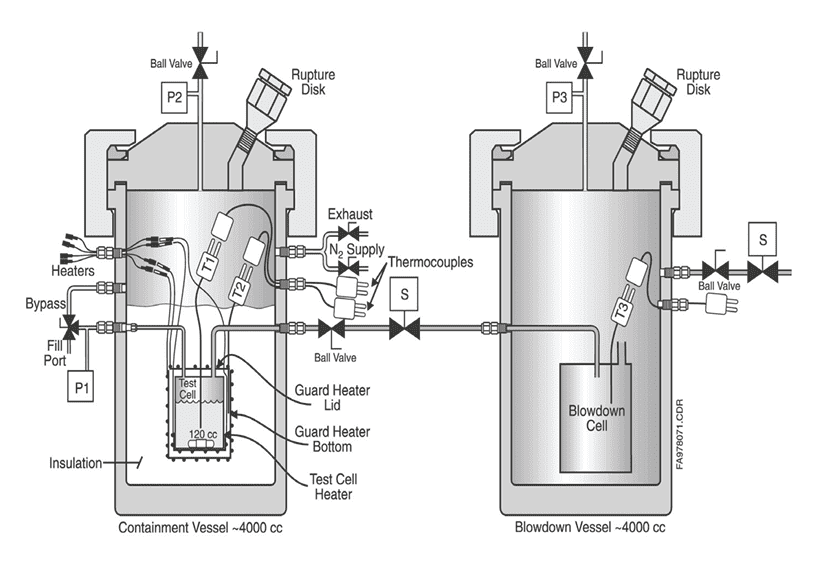

The Vent Sizing Package (VSP) is a low phi calorimeter, meaning its thermal inertia factor (Φ-factor) is close to 1, usually 1.05–1.15. To achieve this, it uses a larger volume of reactants (~80 ml) in a thin-walled metal test cell (~120 ml). While this reduces pressure resistance, the cell sits inside a pressure-controlled autoclave to maintain safe conditions.

A guard heater ensures the test cell stays adiabatic, keeping the ambient temperature equal to the sample temperature. The cell also includes a magnetic agitator, allowing reactions to closely simulate industrial conditions and enabling experimental modeling of potential runaway scenarios.

Test Method

Vent Sizing Package (VSP) tests gather essential data for ERS design and validation. Test cells and methods are chosen based on the desired information, including thermal and pressure data, flow regime, and viscosity effects. Typical approaches include:

-

Closed cell tests

-

Open cell tests for gas generation rate

-

Open cell tests for tempering verification

-

Blowdown-top vent tests for vapor-liquid disengagement characterization

-

Blowdown-bottom vent tests for viscosity characterization

-

Customized tests for specific applications

Data Interpretation

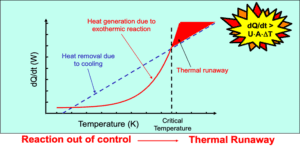

Vent Sizing Package (VSP) provides direct measurements of temperature rise, pressure rise, and peak reaction values. Rates of temperature rise can be converted into heat output rates to determine cooling requirements. Peak pressures inform containment design, while reaction heat is calculated using measured or assumed heat capacities, as long as the cell remains sealed until the peak temperature.

You can obtain:

-

Adiabatic temperature rise and reaction heat

-

Temperature and pressure rise rates

-

Vapor-liquid phase equilibrium data (Antoine plot)

-

Reaction kinetics: activation energy, reaction order, preexponential factor

-

Onset temperature of exothermic reactions with safety factors

-

Time to maximum rate (TMR) and TD24

-

Temperature of no return (TNR) and self-accelerating decomposition temperature (SADT)

-

Gas generation rates

-

Tempering capability for runaway reactions

-

Flow regime identification during vessel venting

-

Viscosity effects on vent flow capacity

-

ERS sizing parameters

Why Perform Vent Sizing Package (VSP) Test?

Vent Sizing Package (VSP) tests are essential for the safe design and operation of emergency relief systems, particularly for gas or vapor-liquid two-phase vent sizing. These tests evaluate the rate at which gases or vapors are released from containers or process systems under overpressure conditions.

VSP tests provide crucial data for:

-

Determining proper sizing and design of pressure relief devices, including relief valves and rupture discs

-

Preventing overpressure events and protecting the integrity of process equipment

-

Establishing maximum allowable process containment pressure and recommended venting capacity

-

Ensuring compliance with regulatory requirements

-

Minimizing the risk of explosions or structural failures

By performing VSP tests, process safety professionals can optimize ERS design, improve overall process safety, and safeguard personnel, facilities, and the environment.

Why Choose Prime Process Safety Center

Our team brings deep expertise in performing Vent Sizing Package (VSP) tests, ensuring accurate and reliable results.

We provide:

-

State-of-the-art equipment and advanced technology: Conduct precise measurements and analyze data thoroughly.

- Testing performed in our ISO/IEC 17025:2017 accredited laboratory: ensuring recognized competency and adherence to international quality standards.

-

Expert understanding of DIERS technology and vent sizing standards: Ensure compliance with industry regulations and best practices.

-

Detailed analysis and reporting: Receive actionable insights and recommendations to optimize system performance and safety.

By choosing our services, you gain confidence in your emergency relief system design and ensure safer process operations.

FAQ

1. What is a vent sizing package apparatus?

The VSP was introduced in 1985 by DIERS for characterizing runaway reactions. The advantages of the VSP include a lightweight test cell and a resulting small Phi factor (low thermal inertia), as well as adiabatic pressure tracking and heat-wait-search capabilities. Moreover, the adiabatic operation permits direct application of temperature and pressure data in large-scale vessels.

2. How does the vent sizing package apparatus work?

The VSP can be considered as a bench-scale chemical reactor housed within a protective containment vessel. It allows for the addition or withdrawal of liquid or gaseous reactants at any point during an experiment. Tests can be conducted in true adiabatic mode, with capability of external heating or cooling.

3. Why is vent sizing important in process industries?

Proper vent sizing ensures the safety and integrity of vessels and process equipment. It prevents dangerous pressure build-up that could lead to equipment failure or other hazardous incidents. Adhering to vent sizing requirements is essential for mitigating risks and maintaining the overall safety of the operation.

4. Are there any specific regulations or codes governing vent sizing?

Yes, there are various industry codes and standards that provide guidelines for vent sizing, such as API 520 and API 521 in the petrochemical industry. These standards ensure compliance with safety regulations and help engineers design reliable pressure relief systems that meet industry requirements.

5. Can the vent sizing package apparatus be used for different industries?

Yes, the vent sizing package apparatus can be utilized in a wide range of industries, including petrochemical, pharmaceutical, food processing, and energy sectors. It is crucial for any industry that deals with processes involving pressure vessels to ensure proper vent sizing and pressure relief for safe operations.