We also offer

What is Breakdown Voltage Testing

Breakdown voltage is the minimum voltage at which a portion of an insulating material becomes electrically conductive. All dielectric materials have a maximum electric field they can withstand before failure—this is called their dielectric breakdown strength (or dielectric breakdown voltage). Breakdown occurs due to:

-

Movement of charge carriers within the material

-

Dielectric or Joule heating

-

Compression from electrostatic forces

This breakdown is often accompanied by a sudden increase in conductivity, forming an electric arc or breakdown path through the material.

Testing Principle

This test applies to solid insulating materials. The sample is conditioned at 25%–60% relative humidity and 23°C for at least 12 hours. A cylindrical electrode is brought into firm contact with the material, which sits on a grounded metal plate.

Voltage is gradually increased until the material’s insulating property fails and a high current flows to the grounded plate. This point is recorded as the breakdown voltage. The process is repeated at least five times on different areas and both sides of the sample.

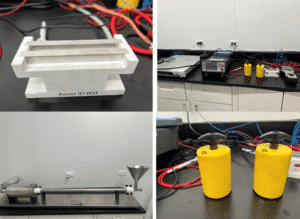

Breakdown Voltage Test Set up

Applicable Standard

Breakdown voltage testing is conducted in accordance with IEC 60243-1, ASTM D3755-20, and Section 9.2 of IEC 61340-4-4.

Data Interpretation

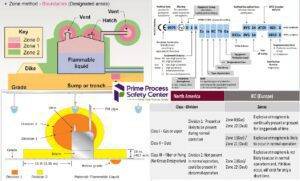

In environments with high levels of static generation—such as pneumatic powder transfer or charge spraying during powder coating—insulating materials with a grounded metal backing can accumulate substantial surface charge. If the material’s breakdown strength is high enough to withstand the electric field, surface charge densities around 300 μC/m² can lead to a propagating brush discharge.

Unlike a standard brush discharge, a propagating brush discharge releases significant energy. It can ignite nearly all flammable gases, vapors, and powders and can cause serious electrostatic shocks. Knowing the breakdown voltage of insulating layers is critical for preventing such discharges, especially in explosive atmospheres.

When to Perform Breakdown Voltage Testing

Breakdown voltage testing applies to a wide range of insulating materials, including:

-

Sheets and films

-

Fabrics and foils

-

Coatings

Understanding and specifying the breakdown voltage is essential to ensuring insulation performance under high-voltage conditions. This helps prevent electrical faults and supports the safe, reliable operation of equipment.

Why Choose Prime Process Safety Center

Prime Process Safety Center is an industry leader in process safety testing. With our ISO/IEC 17025:2017 accredited laboratory, Our experienced laboratory personnel are committed to delivering accurate, reliable, and defensible data that meet both industry and regulatory standards.

What sets us apart:

-

Extensive expertise in breakdown electrostatic testing

-

Advanced, high-precision testing equipment

-

Rigid quality control and testing protocols

-

Insightful data interpretation and recommendations tailored to your application

We prioritize the quality of your results and work diligently to ensure they are trustworthy and actionable.

FAQ

What is Breakdown Voltage?

Answer: Breakdown voltage is the voltage level at which an insulating material loses its ability to resist the flow of electrical current and experiences a significant increase in conductivity, leading to electrical breakdown or failure.

How is Breakdown Voltage Measured?

Answer: Breakdown voltage is often measured using standardized tests such as dielectric strength tests, where the material is subjected to increasing voltage until breakdown occurs.

What Factors Affect the Breakdown Voltage of Insulating Materials?

Answer: Factors influencing breakdown voltage include material composition, purity, thickness, structure, temperature, humidity, surface condition, and presence of defects or impurities.

What are the Types of Breakdowns that Occur in Insulating Materials?

Answer: Breakdown can manifest as partial discharge or complete breakdown. Partial discharge involves localized breakdowns, while complete breakdown involves a sudden and significant increase in current flow.

What Standards Govern Breakdown Voltage Testing?

Answer: Various international standards, such as ASTM (American Society for Testing and Materials) and IEC (International Electrotechnical Commission), provide guidelines for breakdown voltage testing methods.

What Are the Safety Implications of Understanding Breakdown Voltage?

Answer: Understanding breakdown voltage helps in setting safe operating limits, preventing electrical hazards, ensuring equipment safety, and minimizing the risk of electrical failures.