We also offer

What is Accelerating Rate Calorimetry (ARC) Testing

The Accelerating Rate Calorimeter (ARC) is used to evaluate the thermal stability of substances or mixtures under adiabatic conditions. This powerful test identifies the temperature at which exothermic decomposition begins and provides critical data on the kinetics and magnitude of potential runaway reactions.

Applicable Standard:

-

ASTM E1981 – Standard Guide for Assessing Thermal Stability of Materials by Methods of Accelerating Rate Calorimetry

Principle of Operation

The ARC operates in two primary modes:

-

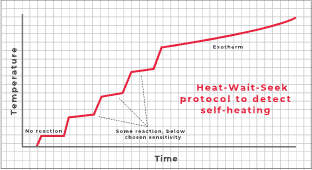

Heat-Wait-Search (HWS) mode

-

Isothermal Age mode

The key principle is to keep the sample under adiabatic conditions once exothermic activity or self-heating is detected. Under these conditions, the reaction accelerates due to the heat generated.

Although ARC experiments can be time-consuming, they are highly effective in capturing reactions with low self-heating rates that could otherwise go unnoticed.

Test Method

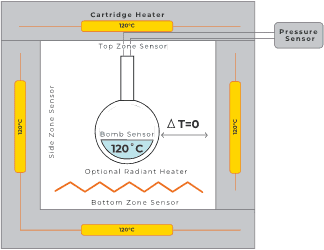

The test is performed using a 10 ml metallic sample bomb filled with 1 to 6 g of material. Depending on the chemical properties, spherical bombs made from different metals are used to avoid corrosion or catalytic interference.

The bomb, fitted with a pressure transducer and temperature sensor, is placed inside an adiabatic enclosure.

-

In the HWS method, the sample is step-heated with a radiant heater.

-

After each step, the system equilibrates and checks for exothermic activity above the threshold (typically 0.02 K·min⁻¹).

-

Once activity is detected, the system continuously monitors the reaction under strict adiabatic conditions until completion.

The ARC cell typically has high thermal inertia (phi factor 1.5–3), excellent pressure capacity (up to several hundred bar), and high sensitivity. However, since the vessel is usually not agitated, studying biphasic systems or triggering reactions with remote additions can be challenging.

Data Interpretation

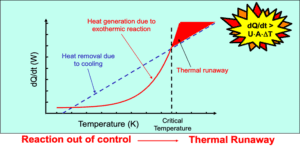

The onset temperature of an exotherm is the lowest temperature where the calorimeter detects heat release above its set threshold. Analyzing the raw temperature, pressure, and time data provides key insights:

-

Reaction rates and magnitudes

-

Heat of reaction, calculated if thermal inertia and sample heat capacity are known

-

Kinetic parameters, including activation energy

Even though the ARC has a relatively high thermal inertia, results can be corrected using the phi factor. This correction helps determine parameters such as:

-

Time to Maximum Rate (TMR)

-

Self-Accelerating Decomposition Temperature (SADT)

For safety, the onset temperature should be applied with a 20–40°C margin, depending on application.

In Summary, ARC Provides:

-

Adiabatic temperature rise and reaction heat

-

Temperature and pressure rise rates

-

Vapor-liquid phase equilibrium data (Antoine plot)

-

Gas generation identification

-

Detection of autocatalytic behavior

-

Reaction kinetic parameters (activation energy, reaction order, pre-exponential factor)

-

Onset temperature of exothermic reactions (with safety factor)

-

Time to maximum rate (TMR) and TD24 (temperature where TMR = 24 hrs)

-

Temperature of no return (TNR)

-

Self-accelerating decomposition temperature (SADT)

-

Induction time for autocatalytic reactions

Why Perform Accelerating Rate Calorimetry (ARC) Testing?

ARC testing plays a critical role in process safety by providing a detailed understanding of how materials behave under adiabatic conditions. It allows you to:

-

Identify exothermic reactions that could lead to thermal runaway

-

Assess the thermal stability of chemicals and mixtures

-

Evaluate the impact of process conditions on reactivity

-

Design safety measures and controls to prevent accidents

This data supports better risk management, safer process design, and protection of personnel, facilities, and the environment.

Why Choose Prime Process Safety Center

-

Expert team: Our highly trained professionals specialize in ARC testing and data interpretation.

-

Advanced equipment: We use state-of-the-art ARC instruments with high sensitivity and reliability.

- Accreditation: Testing performed in our ISO/IEC 17025:2017 accredited laboratory.

-

Thorough analysis: We provide detailed evaluation of results, including reaction kinetics and safety implications.

-

Efficiency and reliability: By outsourcing to our experts, you save time and resources while ensuring accurate data for safer operations.

FAQ

1. What is an Accelerating Rate Calorimeter (ARC)?

An Accelerating Rate Calorimeter (ARC) is a specialized instrument used to evaluate the thermal hazards and determine the temperature and pressure rise rate of reactions, mixtures, and materials. It is extensively used in process safety assessments to identify hazards related to exothermic reactions and reactive materials.

2. How does an ARC work?

An ARC typically consists of a small 10 ml sample bomb that holds the reaction or mixture being analyzed. The instrument monitors the temperature of the sample while a controlled heat source is applied, allowing for the measurement and assessment of the heat release rate. The ARC provides valuable data on the potential dangers of a reaction, including onset temperature, self-heating rates, heat of reaction, and time to maximum rate of heat release.

3. Why is an ARC important in process safety?

ARC plays a critical role in process safety by providing insights into the thermal behavior and hazards of reactions. It helps identify potential runaway reactions and thermal explosions, aids in designing safe reaction conditions, and assists in evaluating and selecting appropriate preventive measures for process safety.

4. What are the advantages of using an ARC?

Using an ARC offers several advantages, such as:

- Early identification of potential thermal hazards during a reaction or with reactive materials.

- Quantitative measurement of heat release rates, allowing for the accurate assessment of reaction hazards.

- Generating valuable data for process safety assessments and enabling the development of effective safety protocols.

- Assisting in the selection and evaluation of preventative measures, such as temperature control, venting systems, or the use of specialized equipment and materials.

5. Can an ARC be used for scale-up considerations?

While an ARC primarily focuses on evaluating small-scale thermal hazards, the data obtained from its measurements can be informative for scale-up considerations. By providing insights into the heat release rate and potential thermal hazards, an ARC can help guide the design and safety considerations when scaling up a process. However, additional measurements and analyses would usually be required to ensure safety at larger production scales.