We also offer

Calorimetric Studies for Process Safety

Process safety plays a critical role in safeguarding industrial facilities and employees. Understanding and managing the potential hazards associated with chemical reactions is vital to prevent accidents, fires, and explosions. One powerful tool that adds value to process safety is calorimetric studies.

Calorimetry provides valuable insights into heat generation, reaction kinetics, and thermal behavior of materials. These insights enable industries to proactively evaluate and mitigate risks, supporting safer operations and regulatory compliance.

Key Laboratory Equipment for Calorimetric Studies

The key laboratory equipment used to obtain necessary data for calorimetric studies includes:

-

Low-Phi Factor Adiabatic Calorimeter (Vent Sizing Package, VSP)

These specialized instruments ensure precise measurement and analysis of heat generation, reaction kinetics, and thermal behavior in various industrial processes.

Steps to Conduct Calorimetric Studies

Evaluating Heat Generation

Calorimetry provides a comprehensive understanding of the heat generation potential of materials used in industrial processes. By accurately measuring heat release rates, researchers can identify hazardous materials prone to self-heating or potential runaway reactions, enabling appropriate preventive measures.

Revealing Reaction Kinetics

Calorimetry enables the determination of reaction kinetics, allowing for safer process design and optimization. By monitoring heat flow during reactions, industries can gain insights into reaction rates, temperature dependencies, and reaction pathways. Understanding these kinetic parameters aids in establishing optimal operating conditions and avoiding temperature excursions that may lead to hazardous situations.

Thermal Behavior Analysis

A thorough understanding of the thermal behavior of materials under various process conditions is essential for process safety. Calorimetry studies provide critical information about key thermal properties such as heat capacity, enthalpy, and thermal stability. This knowledge assists in selecting suitable cooling mechanisms, designing effective heat-transfer systems, and establishing safe operating limits.

Safe-Reaction Scale-Up

Scaling up chemical reactions from the laboratory to industrial production requires careful consideration of process safety. Calorimetric studies help bridge this gap efficiently. By assessing heat profiles, heat transfer limitations, and potential operational issues during scale-up, engineers can proactively address hazards and optimize safety measures for reliable large-scale production.

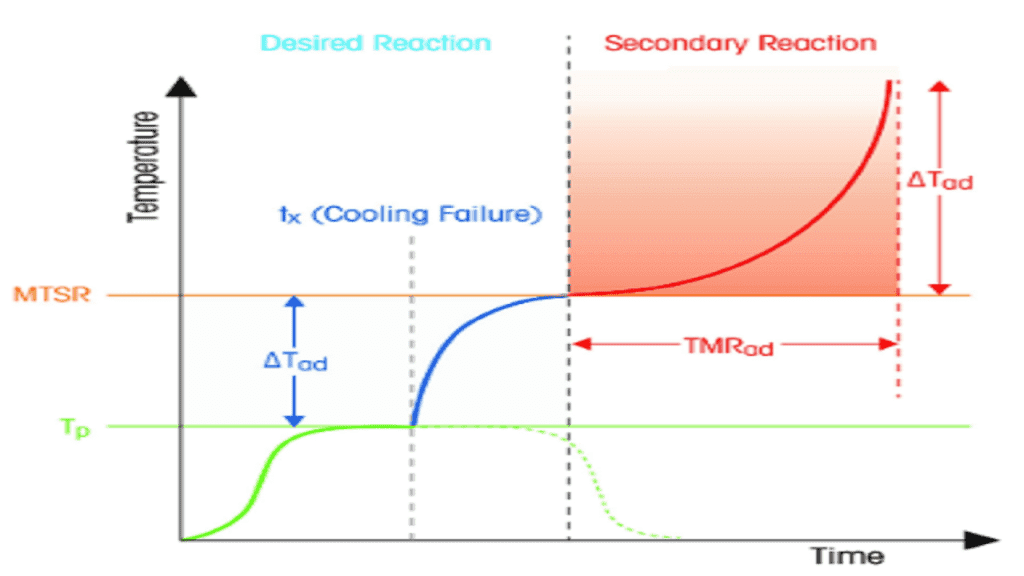

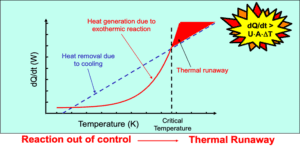

Preventing Thermal Runaways

Thermal runaway reactions are among the most dangerous hazards faced in industrial settings. Calorimetry allows operators to evaluate the potential for such reactions by monitoring heat generation rates, temperature changes, and the onset of exothermicity. Detecting potential thermal runaways early enables industries to take mitigation measures promptly, such as implementing emergency cooling systems or adjusting process conditions to prevent escalation.

Why Perform Calorimetric Studies?

Incorporating calorimetric studies into industrial process safety practices significantly enhances risk assessment and mitigates potential hazards. By leveraging this analytical tool, industries can proactively:

-

Evaluate heat generation

-

Study reaction kinetics

-

Analyze thermal behavior

-

Facilitate safe process scale-up

With calorimetry aiding in the prevention of thermal runaway reactions and offering real-time monitoring capabilities, industries can prioritize safety, protect employees, and uphold regulatory compliance, ensuring a secure operating environment in industrial settings.

Why Choose Prime Process Safety Center

-

Extensive Experience: Our team has years of experience conducting calorimetric studies in industrial settings. We understand the complexities involved and ensure accurate, reliable results every time.

-

State-of-the-Art Equipment: We use advanced, high-quality instruments to precisely measure heat, pressure, and temperature changes, providing dependable data for comprehensive analysis.

-

Customized Solutions: Every process is unique. We develop tailor-made protocols and methodologies to meet each client’s specific operational and safety requirements.

-

Comprehensive Reporting: Our detailed reports clearly present findings, analysis, and recommended actions, serving as valuable tools for process safety improvement and risk mitigation.

Partnering with Prime Process Safety Center means working with a reliable team focused on expertise, technology, and safety. We help you understand and enhance the safety aspects of your processes through professional calorimetric studies.

FAQ

1. What is a calorimetric study?

A calorimetric study is a scientific investigation conducted to measure and analyze heat release, temperature changes, and pressure variations in industrial processes. It helps evaluate the thermal hazards associated with materials and processes to ensure safety in industrial settings.

2. Why are calorimetric studies important?

Calorimetric studies provide critical information on the heat release rates, reaction kinetics, and potential hazards in industrial processes. This information helps identify and mitigate potential risks, design safer processes, and ensure compliance with regulatory standards.

3. What types of processes can benefit from calorimetric studies?

A wide range of processes can benefit from calorimetric studies, including chemical reactions, manufacturing operations, energy production, combustion processes, storage and handling of hazardous materials, and industrial equipment design and operation.

4. How are calorimetric studies conducted?

Calorimetric studies involve the use of specialized equipment, such as differential scanning calorimeters (DSC), Differential Thermal Analysis (DTA), Accelerating Rate Calorimeters (ARC), Reaction Calorimeters (RC1, for example), and adiabatic calorimeters such as Vent Sizing Package (VSP). These instruments are used to measure and analyze heat release, temperature changes, and pressure variations during the process under study.

5. What are the potential applications of calorimetric studies?

Calorimetric studies can be applied in various areas, including the assessment of thermal stability of chemicals, evaluation of runaway reactions, determination of reaction kinetics, investigation of dust explosions and flammable gas hazards, and characterization of thermal behavior during storage and transportation.

6. Can calorimetric studies help in process optimization?

Yes, calorimetric studies can provide valuable insights for process optimization. By understanding the thermal behavior and potential hazards associated with a process, adjustments can be made to improve efficiency, reduce costs, and enhance safety.

7. Who should consider conducting calorimetric studies?

Industries involved in chemical manufacturing, petroleum refining, pharmaceuticals, power generation, food processing, and any other process involving heat release or potential hazards can benefit from conducting calorimetric studies.

8. Are calorimetric studies the only approach for process safety evaluations?

Calorimetric studies are one of the valuable tools for process safety evaluations, but they should be combined with other methods, such as hazard identification, risk analysis, and process safety audits, to ensure a comprehensive approach.

9. How long does a calorimetric study typically take?

The duration of a calorimetric study depends on various factors, such as the complexity of the process, the number of tests required, and the availability of resources. Generally, a study can take anywhere from a few days to several weeks to complete.

10. What information can I expect to receive from a calorimetric study?

After completing a calorimetric study, you can expect to receive a detailed report that includes experimental results, data analysis, calculations, observations, and recommendations for process safety improvements. The report serves as a valuable resource for decision-making and risk mitigation strategies.