We also offer

Two-Phase Relief System Design Using DIERS Technology

In industries where two-phase fluids, such as liquid–gas or vapor mixtures, are present, it is crucial to have robust emergency relief systems in place to prevent overpressure scenarios that could lead to equipment failure or catastrophic incidents.

Traditional relief system design methods often fail to account for the unique complexities of two-phase relief, particularly in uncontrolled runaway reaction scenarios.

To address this challenge, the Design Institute for Emergency Relief Systems (DIERS) developed advanced technologies and methodologies specifically tailored for two-phase relief design.

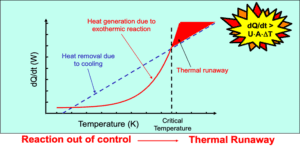

Understanding Runaway Reactions

Runaway reactions pose a major threat in chemical processes because they can cause a rapid increase in temperature and pressure beyond equipment capacity. This excessive pressure can exceed design limits and result in catastrophic events — such as the 2007 T2 Laboratories incident in Jacksonville, Florida, investigated by the U.S. Chemical Safety and Hazard Investigation Board (CSB).

To effectively mitigate such scenarios, it is essential to:

-

Understand the behavior and kinetics of runaway reactions

-

Identify potential failure modes

-

Design emergency relief systems capable of safely venting excess pressure

A thorough understanding of reaction behavior enables engineers to create effective, data-driven emergency relief systems that can control and mitigate runaway conditions.

DIERS Technology and Its Application

DIERS technology provides a systematic and scientific framework for the design of two-phase emergency relief systems. It combines experimental data, mathematical modeling, and engineering expertise to ensure accuracy and reliability.

Key aspects of DIERS technology include:

-

Runaway reaction kinetics analysis

-

Modeling of liquid flashing and two-phase flow behavior

-

Evaluation of hydraulic phenomena during emergencies

By accurately simulating these physical and chemical phenomena, DIERS methodology enables engineers to design tailored relief systems that meet specific process conditions and ensure safety during overpressure events.

Compliance with Industry Standards

Implementing DIERS technology ensures compliance with key process safety standards and regulations.

-

OSHA (CFR 1910.119 Process Safety Management Regulation, 1992):

Recognizes DIERS technology as “recognized and generally accepted good engineering practice (RAGAGEP).”OSHA also recommends re-evaluating relief system capacity using AIChE DIERS methodology in cases involving runaway reaction venting. -

ASME and API Standards:

DIERS-based design methods align with the international standards defined by the American Society of Mechanical Engineers (ASME) and the American Petroleum Institute (API 520 and API 521).

Integrating these standards ensures that the two-phase emergency relief system meets global compliance requirements and provides a safer operating environment.

Procedures for Two-Phase Relief System Design Using DIERS Technology

Designing a two-phase relief system using DIERS methodology involves a structured, multi-step process that ensures reliability, accuracy, and compliance.

1. Critical Parameters and Scenario Analysis

DIERS technology emphasizes the identification of key process parameters influencing runaway reactions, including:

-

Reaction system type (vapor, gassy, or hybrid)

-

Reaction kinetics and heat generation rate

-

Vessel geometry and size

-

Environmental and process conditions

Conducting scenario-based analysis helps define realistic design parameters and ensures the relief system is properly sized and equipped for potential overpressure events.

2. Identification of Two-Phase Relief

The first step in applying DIERS technology is identifying potential two-phase relief scenarios within process equipment. This involves assessing conditions that may lead to two-phase flow, such as:

-

Vaporization of liquids in vessels

-

Flashing due to sudden pressure drops in pipes

-

Natural evaporation in heat exchangers

Recognizing these conditions early allows engineers to focus the relief design on systems most likely to experience two-phase flow during an emergency.

3. Two-Phase Hydraulic Modeling

DIERS methodology uses drift-flux hydraulic modeling tools to simulate the behavior of two-phase fluids, such as homogeneous, bubbly, or churn-turbulent flow regimes.

This modeling process evaluates:

-

Fluid properties and flow rates

-

Pressure drop and temperature profiles

-

Liquid swelling and expansion

The resulting models help engineers predict flow behavior and optimize relief system performance, ensuring safe and efficient discharge during overpressure conditions.

4. Relief Load Calculations

Once the two-phase behavior has been modeled, the next step is performing relief load calculations to determine the magnitude of the potential venting event.

Using DIERS technology, engineers calculate:

-

Mass, volume, and flow rates of the two-phase mixture

-

Potential relief rates under different process scenarios

-

The maximum required capacity of the relief device

These calculations ensure that the relief system is properly sized to handle the worst-case conditions, preventing overpressure and ensuring safe discharge during emergencies.

5. Relief Device Sizing and Selection

Proper sizing and selection of relief devices are critical to the success of any emergency relief system for runaway reactions.

DIERS technology assists engineers in:

-

Determining the correct size of pressure relief valves, rupture discs, or other relief devices

-

Matching device capacity to process pressure and flow conditions

-

Ensuring equipment and personnel protection under extreme scenarios

By following DIERS-based methods, the final relief system design ensures both technical accuracy and regulatory compliance.

6. System Integration and Validation

After the relief devices are selected and sized, they must be integrated into the overall plant design. This includes the proper configuration of:

-

Isolation valves

-

Vent headers and discharge systems

-

Interconnecting components to form a complete, functional network

DIERS technology provides detailed guidance on system integration and performance validation, ensuring that the relief system meets safety standards and performs as expected during pressure relief events.

Why Use DIERS Technology?

Industries that handle liquid–gas two-phase mixtures—such as petrochemical, pharmaceutical, and chemical manufacturing plants—face unique challenges in designing effective emergency relief systems.

Failing to properly account for two-phase flow can lead to:

-

Equipment damage

-

Environmental pollution

-

Serious safety risks to personnel

DIERS (Design Institute for Emergency Relief Systems) technology provides a reliable solution by predicting when two-phase flow will occur and quantifying vapor–liquid swell.

Key benefits of implementing DIERS technology include:

-

Accurately predicts the onset and magnitude of two-phase relief

-

Determines the required relief area for two-phase flow, which is typically larger than that for vapor-only or subcooled liquid flow

-

Provides a scientific, standardized methodology accepted across multiple industries

-

Ensures that the relief system design is safe, efficient, and defensible

For facilities dealing with liquid–gas mixtures or other two-phase systems, adopting DIERS technology is essential to ensure process safety and regulatory compliance.

Why Choose Prime Process Safety Center

Choosing the right partner to implement DIERS technology can make a significant difference in the safety, reliability, and compliance of your two-phase emergency relief system.

At Prime Process Safety Center, we provide specialized expertise and proven methodologies for DIERS-based relief system design.

Our Advantages:

-

Expertise:

Extensive experience applying DIERS technology to two-phase emergency relief systems across diverse industries. -

Compliance:

Full alignment with OSHA, ASME, and API standards to ensure your system meets recognized global requirements. -

Safety:

DIERS is acknowledged by OSHA as a “Recognized and generally accepted good engineering practice (RAGAGEP),” ensuring safer design and operation. -

Accuracy:

Reliable re-evaluation of relief system size and capacity, especially for runaway reaction venting incidents. -

International Standards:

Incorporation of ASME and API (520, 521) guidelines for global compatibility and safety assurance. -

Assurance:

Partnering with us guarantees that your system is designed and validated using industry-accepted, data-driven practices.

FAQ

1. What is DIERS technology and how does it relate to runaway reactions?

DIERS (Design Institute for Emergency Relief Systems) technology is a methodology used for the design, analysis, and evaluation of emergency relief systems in various industries. It is commonly used to design relief systems for managing runaway reactions, ensuring safety in process industries.

2. What is a runaway reaction and why is it a concern?

A runaway reaction refers to a situation where a chemical reaction becomes uncontrollable and generates excessive heat or pressure, which can lead to equipment damage, hazardous releases, and potential safety risks to personnel and the environment.

3. How can DIERS technology help with the design of relief systems for runaway reactions?

DIERS technology provides a systematic approach to analyze and evaluate the reaction kinetics, thermal data, and process conditions to accurately design emergency relief systems that can effectively handle and manage runaway reactions.

4. Can DIERS technology be used to prevent runaway reactions?

While DIERS technology primarily focuses on the design of emergency relief systems, it can indirectly help in preventing runaway reactions by providing insights into reaction kinetics, process parameters, and potential deviations that can trigger a runaway reaction.

5. Are there specific guidelines or standards associated with using DIERS technology for runaway reactions?

Yes, the AIChE's (American Institute of Chemical Engineers) Center for Chemical Process Safety has developed guidelines and recommended practices for using DIERS technology to design relief systems for runaway reactions, such as the Guidelines for Pressure Relief and Effluent Handling Systems.

6. Is specialized training required to implement DIERS technology for runaway reactions?

A thorough understanding of chemical process engineering and reaction kinetics is beneficial for implementing DIERS technology for runaway reactions. Additional training or guidance from experts in the field is recommended to ensure accurate and effective use of the technology.

7. Can DIERS technology be applied to all types of runaway reactions?

Yes, DIERS technology can be applied to various types of runaway reactions, including exothermic reactions, polymerization reactions, and reactive distillation processes, among others. However, it is important to note that the specific characteristics and complexities of the reaction will influence the design of the relief system.

8. Are there any case studies or examples showcasing the successful implementation of DIERS technology for runaway reactions?

Yes, there are many case studies and examples available that highlight the successful application of DIERS technology for designing relief systems for runaway reactions. These case studies can provide valuable insights into best practices and industry-specific considerations.

9. Can DIERS technology help with the evaluation and optimization of existing relief systems for runaway reactions?

Yes, DIERS technology can be used to evaluate and optimize existing relief systems for runaway reactions. By conducting a thorough analysis and utilizing advanced modeling techniques, potential deficiencies in the existing system can be identified, and necessary modifications or upgrades can be recommended.

10. How can I get started with utilizing DIERS technology for designing relief systems for runaway reactions?

To get started, it is recommended to consult with experts who are experienced in using DIERS technology for runaway reactions. They can provide guidance, conduct process evaluations, and assist with the design and implementation of robust relief systems to manage runaway reactions effectively.