We also offer

What is Limiting Oxygen Concentration of Combustible Gas (LOC)

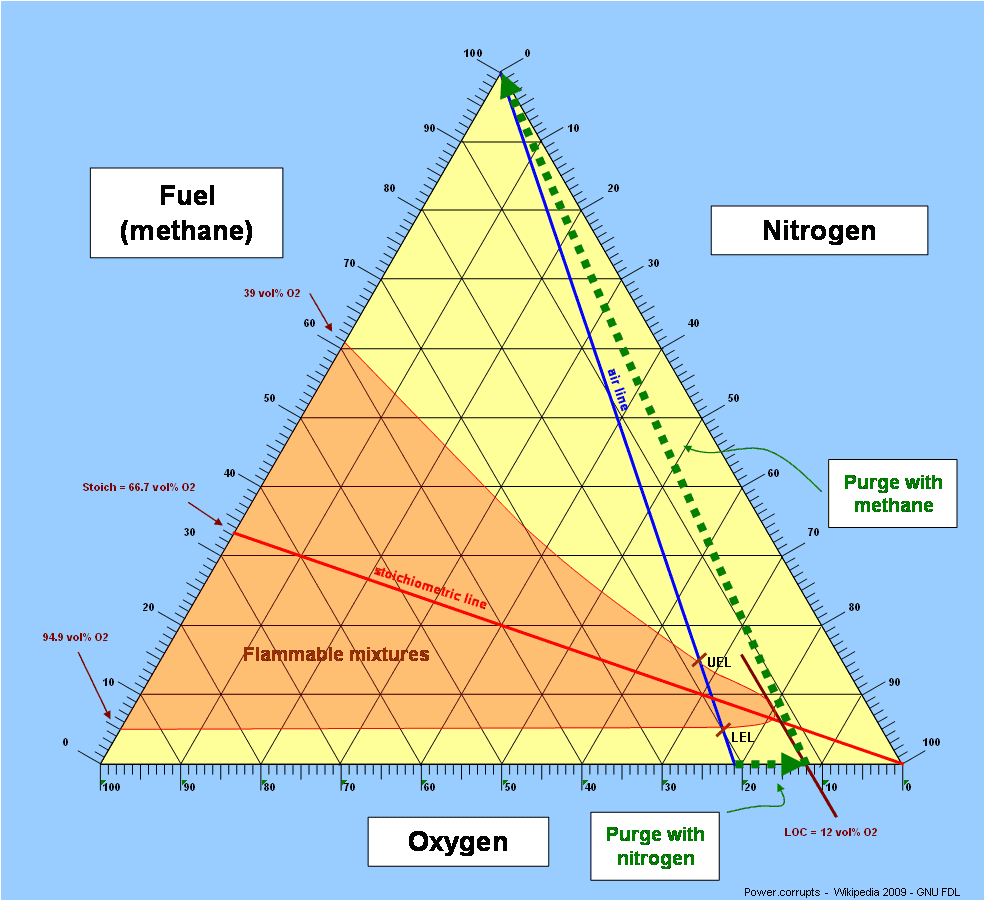

The Limiting Oxygen Concentration (LOC) for a combustible gas is the minimum oxygen level in air at which combustion or explosion involving that gas can no longer be sustained — even when an ignition source or sufficient fuel is present. It defines the safety threshold below which the gas-air mixture cannot support ignition.

Limiting Oxygen Concentration (LOC) Test

Testing Principle and Methodology

LOC testing for combustible gases follows a procedure similar to the LOC determination for dusts, except there is no dust dispersion step.

The process begins by reducing the pressure in the test sphere to below 0.4 bar to create space for the combustible gas. For example:

-

For a 5 vol % methane concentration, the partial pressure is 0.05 bar, requiring evacuation to 0.35 bar.

-

For a 10 vol % methane concentration, the partial pressure is 0.10 bar, requiring evacuation to 0.30 bar.

The oxygen concentration is then gradually reduced from 21% until it reaches the point where combustion can no longer occur. This oxygen level is recorded as the Limiting Oxygen Concentration.

Applicable Standards

LOC testing is performed according to: EN 15967 – Determination of Maximum Explosion Pressure (Pmax) and Rate of Pressure Rise (Kg) of Gases

Data Interpretation

The LOC is determined based on the pressure ratio generated in the test sphere:

-

A pressure ratio of 2.0 or higher indicates ignition of the gas.

-

The lowest oxygen concentration at which ignition no longer occurs is recorded as the Limiting Oxygen Concentration.

When to Perform Limiting Oxygen Concentration (LOC) Testing

LOC testing is critical in situations where inerting is used to prevent gas explosions. Establishing the LOC helps determine the maximum allowable oxygen concentration in a process for safe operation.

This test is recommended:

-

During new material introductions

-

For regulatory compliance checks

-

After incidents involving combustible gases

-

As part of periodic safety assessments

It ensures workplace safety and prevents fire or explosion hazards in environments where combustible gases are present.

Why Choose Prime Process Safety Center

Prime Process Safety Center provides accurate and defensible LOC testing for combustible gases, meeting both industry and regulatory standards.

We offer:

-

Expertise in gas explosion severity testing

-

State-of-the-art testing equipment for precise, sensitive measurements

-

Strict protocols and quality controls to ensure consistent results

-

Expert data analysis with practical safety recommendations tailored to your operations

FAQ

What causes combustible gas explosions?

Combustible gas explosions are typically caused by the ignition of a gas-air mixture in the presence of an ignition source. Common factors include leaks, inadequate ventilation, and the presence of an open flame or spark.

How can I prevent combustible gas explosions in my workplace or home?

Prevention measures include regular gas leak inspections, proper ventilation, using explosion-proof equipment, and following safety guidelines for handling and storing combustible gases. Additionally, educate individuals on proper procedures and emergency response protocols.

What should I do in case of a suspected gas leak?

If you suspect a gas leak, evacuate the area immediately. Do not use electrical switches or devices, as they can create sparks. Contact emergency services and the gas company. Wait for professionals to assess and address the situation.

Are there specific safety standards for handling combustible gases?

Yes, there are industry-specific safety standards and regulations that outline guidelines for the handling, storage, and transportation of combustible gases. Compliance with these standards is crucial for minimizing the risk of explosions.

How can I ensure the proper storage of combustible gases?

Store combustible gases in well-ventilated areas away from ignition sources. Use approved containers and follow guidelines for proper labeling. Implement safety measures such as fire-resistant cabinets and ensure employees are trained on safe storage practices.