We also offer

What Is Bow-Tie Analysis?

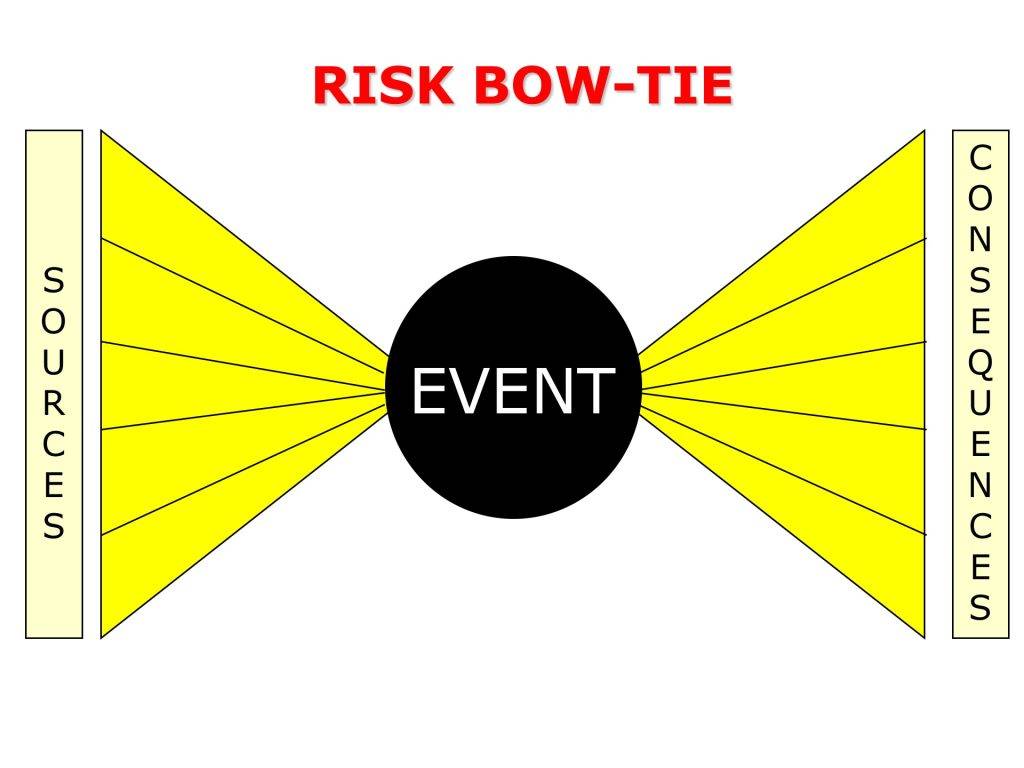

Bow-Tie Analysis is a powerful risk management tool used to visualize and assess the pathways leading to a hazardous event and the consequences that may follow. Named after its distinctive shape, this method helps organizations in high-risk industries—such as chemical manufacturing, oil and gas, and pharmaceuticals—understand, communicate, and control risks.

The left side of the bow-tie diagram shows the threats (or causes) that could lead to a central hazardous event (the “knot”), while the right side displays the potential consequences of that event. This dual-structured approach provides a clear, visual representation of how incidents can occur and how they can be prevented or mitigated.

Why Perform Bow-Tie Analysis?

Bow-Tie Analysis offers a structured, visual method to:

-

Identify causes and consequences of potential incidents

-

Assess the effectiveness of existing safety barriers

-

Highlight gaps where additional controls are needed

-

Enhance safety awareness across all levels of your organization

-

Improve regulatory compliance and risk communication

-

Support training, decision-making, and continuous improvement

This technique is especially valuable in process industries where complex systems and human factors play a role in potential failures. It not only helps in proactively preventing incidents but also strengthens your organization’s response planning and safety culture.

How Is Bow-Tie Analysis Conducted?

Implementing a Bow-Tie Analysis involves the following steps:

-

Identify the Central Hazardous Event

Define the event that poses the highest risk (e.g., fire, explosion, toxic release). -

List Threats and Consequences

Identify all possible causes (threats) and outcomes (consequences) of the central event. -

Build the Bow-Tie Diagram

Place the central event in the middle, with threats on the left and consequences on the right. -

Map Safety Barriers

Show existing preventive barriers (between threats and event) and mitigation barriers (between event and consequences). -

Evaluate Barrier Effectiveness

Assess each barrier’s strength, reliability, and any weaknesses or failure points. -

Involve a Multidisciplinary Team

Engage personnel from operations, maintenance, engineering, and safety to gain a full-spectrum view. -

Prioritize Risk Reduction Efforts

Identify which threats and consequences require urgent attention or improved controls. -

Integrate with Risk Management Systems

Align the analysis with existing risk assessments, PHA, and safety programs. -

Document the Process

Keep detailed records for regulatory audits, safety reviews, and future reference. -

Train Staff Using the Diagram

Use the bow-tie visual as a training and communication tool for all stakeholders. -

Develop and Implement an Action Plan

Address risks by implementing new controls or improving current ones. -

Review and Update Regularly

Keep your Bow-Tie Analysis up to date as operations or regulations change.

Why Choose Prime Process Safety Center

Partnering with Prime Process Safety Center gives you expert guidance and support throughout the Bow-Tie Analysis process. Here’s what sets us apart:

-

Industry Expertise

Our team brings deep experience in process safety and hazard analysis, especially in high-risk industries. -

Customized Approach

We tailor the Bow-Tie Analysis to reflect the unique risks and needs of your operation. -

Clear Risk Visualization

Our diagrams provide a concise, intuitive view of threats, consequences, and controls. -

Quality-Focused Execution

We deliver detailed, actionable results—no shortcuts, no oversights. -

Effective Communication Tools

Our visuals make it easy to communicate risks across all organizational levels. -

Integration with Existing Systems

We align your Bow-Tie Analysis with your current PHA, SOPs, and risk management frameworks. -

Strategic Risk Mitigation

We go beyond identifying risks—we recommend meaningful solutions. -

Training & Facilitation Support

We include Facilitation and Scribing Personnel to support documentation, learning, and implementation. -

Regulatory Compliance

We help ensure your safety practices meet OSHA, EPA, and other industry standards. -

Commitment to Continuous Improvement

Our partnership doesn’t end at delivery—we support ongoing updates, audits, and enhancements.

FAQ

1. What is Bow-Tie Analysis?

Bow-Tie Analysis is a risk management tool that visually maps out the causes and consequences of potential hazardous events in a process, illustrating preventive and mitigative controls in a bow-tie shaped diagram.

2. Why is Bow-Tie Analysis important in the process industry?

It's important for visually identifying and understanding the risks associated with complex industrial processes, enhancing safety management by clearly illustrating potential hazards and control measures.

3. How does Bow-Tie Analysis work?

Bow-Tie Analysis works by placing a potential hazardous event at the center of a diagram, with the left side showing contributing threats (causes) and the right side showing potential consequences, linked by control measures.

4. What are the key components of a Bow-Tie Diagram?

The key components include the central hazardous event, threats, consequences, preventive controls (barriers to prevent the event), and mitigative controls (barriers to reduce the impact of the event).

5. Who should be involved in conducting Bow-Tie Analysis?

A multidisciplinary team including safety experts, process engineers, operations staff, and maintenance personnel should be involved for a comprehensive perspective.

6. Can Bow-Tie Analysis be used for all types of hazards?

Yes, it can be applied to a wide range of hazards, especially those that are complex and have multiple potential causes and consequences.

7. What is the difference between Bow-Tie Analysis and other risk assessment tools?

Bow-Tie Analysis uniquely visualizes both the preventive and reactive sides of risk management in one diagram, offering a more integrated view compared to other tools that may focus on either side.

8. How often should Bow-Tie Analysis be updated?

It should be reviewed and updated regularly, especially after significant changes in processes, equipment, or following an incident.

9. How does Bow-Tie Analysis improve safety in the process industry?

It improves safety by systematically identifying and evaluating potential risks, ensuring effective control measures are in place and highlighting areas where additional safety measures may be needed.

10. Is Bow-Tie Analysis suitable for communication and training?

Yes, the visual and straightforward nature of Bow-Tie Diagrams makes them excellent tools for communication and training purposes across different levels of an organization.