Background of Combustible Dust Cleaning

Maintaining effective combustible dust cleaning practices in facilities that handle or process combustible dust is critical. Over the past 30 years, investigations by the Chemical Safety Board and other agencies into serious dust explosions have consistently identified common causal factors, with inadequate housekeeping and dust cleaning programs being among the most significant. These programs are essential for keeping combustible dust accumulations at safe levels and preventing flash fires or explosions.

Plant management must actively control combustible dust accumulations through structured cleaning practices to protect employees and property from secondary flash fires and explosions. Designing and implementing a rigorous combustible dust cleaning program provides a systematic approach to managing dust buildup throughout the facility.

A well-designed combustible dust cleaning program also establishes defined cleaning frequencies to ensure dust levels remain below hazardous accumulation limits and includes clear timetables for addressing unscheduled spills or abnormal dust releases.

Why Combustible Dust Cleaning Is Critical for Preventing Secondary Explosions

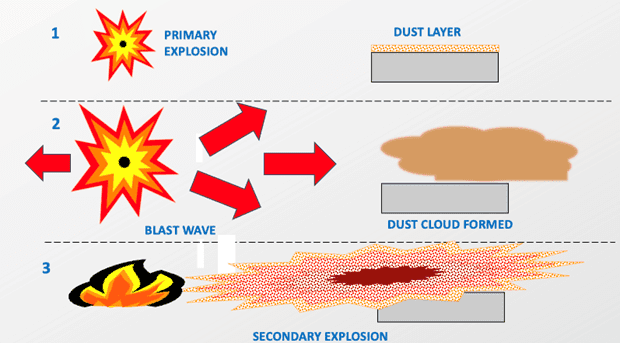

Secondary dust explosions occur when accumulated combustible dust on floors, elevated surfaces, or equipment becomes airborne and ignites following a primary event. These secondary explosions are often more destructive than the initial ignition because the first blast can disperse additional dust into the air, creating fuel for subsequent explosions.

Effective combustible dust cleaning is critical in preventing secondary explosions by limiting the amount of dust available to become airborne. Controlling dust accumulations through routine and unscheduled cleaning reduces the likelihood that a primary incident will escalate into multiple, high-consequence secondary explosions.

Combustible Dust Cleaning Requirements and Applicable Standards

-

NFPA Standards: NFPA requires facilities to implement effective combustible dust cleaning programs to control secondary explosion risks, which are often more severe than primary incidents.

-

OSHA Housekeeping Standard (29 CFR Part 1910.22): Employers must maintain clean and orderly workplaces, passageways, storerooms, and service rooms. Floors should remain clean and dry. This standard allows safety officers to determine appropriate cleaning methods and frequencies.

-

NFPA 652 and 654: These standards specifically require facilities to remove combustible dust from floors, structural members, and other surfaces during operations. Each facility must develop a written combustible dust cleaning program that defines cleaning methods and frequency. NFPA 654 provides detailed guidance for establishing and maintaining thorough cleaning procedures to minimize explosion hazards.

How Combustible Dust Cleaning Limits Are Determined

Facilities use several methods to assess the risk of flash fires or explosions from accumulated combustible dust. These methods help determine safe dust accumulation limits, which guide cleaning frequency and procedures to prevent hazardous levels.

The Layer Depth Criterion Method

This method sets a maximum allowable dust layer thickness based on the dust’s bulk density. It calculates the layer depth criterion (LD) by using a reference bulk density value and adjusting it for the specific dust. This criterion helps identify when dust accumulation becomes hazardous. To calculate LD, multiply the benchmark accumulation level of 1/32 inch (from NFPA 654, section 6.1.3) by 75 lb/ft³ (the reference bulk density), then divide the result by the bulk density (ρ) of the dust being evaluated. This gives the new maximum allowable dust thickness or layer depth criterion.

Equation 1: LD (in.) = [(1/32) * 75]/ρdust

Mass Method A

This approach checks for flash fire or explosion hazards by measuring the total dust mass accumulated outside the equipment. It uses specific equations to set threshold dust masses that indicate hazard levels. Because it doesn’t require detailed physical property data, this method is simpler, conservative, and practical. When the total dust outside the equipment exceeds the values from Equations 2 and 3, the area qualifies as a dust flash fire or explosion hazard. The threshold dust mass that defines a building or room as a dust explosion hazard area, M_basic-exp, is calculated using the following equation:

Equation 2: M basic-exp = 0.004*Afloor*H

where:

Mbasic-exp =threshold dust mass (kg) based on building damage criterion

Afloor=lesser of enclosure floor area (m2) or 2000 m2

H=lesser of enclosure ceiling height (m) or 12 m

The threshold dust mass establishing a building or room as a dust flash-fire hazard area, Mbasic-fire, is determined by the following equation:

Equation 3: Mbasic-fire = 0.02*Afloor

Where:

M basic fire is threshold mass (kg) based on personnel fire exposure criteria.

A floor is lesser of enclosure floor area (m2) or 2000 m2

These equations do not require measurement of any physical or combustibility properties for an application and tend to lead to a more conservative outcome.

Mass Method B

A more complex method involves separate equations to calculate the threshold dust mass establishing the hazard. It requires inputs on various parameters such as building strength, worst-case dust concentrations, dust entrainment factors, and the probability of flame impingement. This method is detailed in NFPA 654 and provides a thorough hazard assessment but can be challenging due to the need for precise data. NFPA 654 (section 6.1.5.1) provides more information with regard to this method.

Risk-Based Methods for Evaluating Combustible Dust Cleaning Needs

The risk-based method involves a documented evaluation, accepted by the authority having jurisdiction (AHJ), to determine whether a dust explosion or flash fire hazard exists. It focuses on material properties, facility design, and operational conditions, making it particularly useful for unique or challenging dusts.

This method typically requires specialist expertise and specific test data on the dust being handled. It is most applicable when standard accumulation or mass methods may not fully capture the hazard, such as in cases where:

-

Dust has a low bulk density

-

Dust is hygroscopic (absorbs moisture)

-

Dust has low ignition sensitivity

-

The particulate nature of the material makes forming fine dust clouds difficult

By incorporating these factors, the risk-based approach allows facilities to tailor combustible dust cleaning programs to effectively manage hazards that might not be addressed by standard cleaning thresholds alone.

Summary of Combustible Dust Cleaning Threshold Methods

An effective combustible dust cleaning program should maintain dust accumulation levels below thresholds that could cause flash fires or explosions if the dust becomes airborne. Regular inspections and timely cleaning help ensure these safety goals are consistently met.

Facilities can use the Layer Depth Criterion or Mass Method A to establish cleaning thresholds and manage flash fire and explosion risks. When these methods are impractical or insufficient, a risk-based evaluation may be applied for more complex dust or operational scenarios.

Implementing a well-structured dust cleaning program can significantly reduce the likelihood of a major industrial dust explosion and protect both personnel and property.

How Combustible Dust Cleaning Affects Hazardous Area Classification

A well-designed combustible dust cleaning program directly influences hazardous area classification and electrical safety in facilities handling dust. Key components include:

-

Routine Cleaning: Regular cleaning prevents dust buildup on floors, walls, equipment, ducts, hoods, ledges, beams, and hidden areas (e.g., above ceilings or inside electrical enclosures).

-

Inspection & Frequency: Schedule inspections to monitor dust levels and adjust cleaning frequency to ensure dust remains below hazardous limits.

-

Spill Cleanup: Establish clear timelines for addressing spills or short-term dust accumulations to prevent hazardous conditions.

-

Electrical Classification:

Refer to NFPA 70 (NEC) Article 500.4(B) and NFPA 499 for hazardous area classification.-

Division 1: Dust is airborne under normal conditions or during equipment failure; dust layers exceed 1/8 inch.

-

Division 2: Dust is usually settled but may become airborne during malfunctions.

-

-

Role of Cleaning: Consistent combustible dust cleaning determines whether an area is classified as Division 1, Division 2, or unclassified, based on dust thickness and accumulation patterns.

Table 1: Unscheduled Housekeeping

| Accumulation on the Worst Single Square Meter of Surface | Longest Time to Complete Unscheduled Local Cleaning of Floor-Accessible Areas | Longest Time to Complete Unscheduled Local Cleaning of Areas |

|---|---|---|

| >1 to 2 times threshold dust Mass/accumulation | 8 hours | 24 hours |

| >2 to 4 times threshold dust Mass/accumulation | 4 hours | 12 hours |

| >4 times threshold dust mass /accumulation | 1 hour | 3 hours |

Table 2: Cleaning frequencies based on the depth of the dust layer

| Depth of Dust Accumulation (in.) | Frequency | Housekeeping Requirements | Area Electrical Classification |

|---|---|---|---|

| < 1/32 | Continuous / frequent | Clean up as necessary to maintain an average accumulation below 1/64 in. | Unclassified; however, electrical enclosures should be dust-tight |

| 1/32 to 1/8 | Infrequent | Clean up during same shift | Unclassified; however, electrical enclosures should be dust-tight |

| 1/32 to 1/8 | Continuous / frequent | Clean as necessary to maintain an average accumulation below 1/16 in. | Class II, Division 2 |

| > 1/8 | Infrequent | Immediately shut down and clean | Class II, Division 2 |

Combustible Dust Cleaning Procedures and Methods

Visual Baseline and Cleaning Frequency

Establish a visual baseline in process areas to observe and measure dust over specific periods (e.g., a shift or day). This helps determine proper cleaning frequency and ensures dust accumulation remains below the 1/32 inch benchmark.

Design dust-handling systems—including exhaust ducts, dust collectors, vessels, and processing equipment—to prevent fugitive dust from entering the work area.

Clean horizontal surfaces, floors, decks, walls, bulkheads, and equipment components such as ducts, pipes, hoods, ledges, beams, stair rails, and concealed surfaces above ceilings regularly. Cleaning frequency should prevent dust accumulations of 1/32 inch or more.

Cleaning methods should avoid generating dust clouds that can resettle at higher elevations.

Vacuum Cleaning Equipment and Practices

Vacuum cleaning—either via central systems or mobile units—is the preferred combustible dust cleaning method.

-

Central systems provide greater storage capacity and multiple connection points, reducing the need to move equipment.

-

Mobile vacuum cleaners are acceptable if they meet safety standards.

Requirements for Class II areas:

-

Equipment must be listed for use in hazardous areas.

-

Hoses and tools must be static-dissipative or conductive and properly grounded.

Additional safety measures for portable vacuums:

-

Conduct a dust hazard analysis (DHA) before use.

-

Use hoses and tools suitable for combustible dust.

-

Avoid vacuuming materials with hot embers or sparks.

For unclassified areas:

-

Use static-dissipative or conductive hoses.

-

Bond and ground all conductive components.

-

Position fans and motors on the clean side of filtration systems unless rated for Class II, Division 1.

-

Avoid paper filter elements when collecting liquids or wet materials.

Vacuum System Safety Considerations

When using a vacuum system, facilities should:

-

Never vacuum ignition sources or glowing embers.

-

Follow the manufacturer’s instructions.

-

Use only approved accessories.

-

Empty the vacuum before and after each use.

-

Inspect filter pleats for excessive material buildup.

-

Check power cables for wear and replace them if needed.

Central vacuum systems should meet NFPA 652, Section 8.3.3 requirements:

-

Maintain minimum conveying velocities with one or multiple operators.

-

Use hose lengths and diameters appropriate for the application.

-

When collecting ignition-sensitive materials, ensure all tools are grounded, static dissipative or metallic, and constructed for use in hazardous areas.

Manual Cleaning Methods

- Scoops, brooms, and brushes may be used, but care must be taken to avoid creating dust clouds.

- Use soft brooms or natural fiber brushes to minimize dust dispersion.

- Avoid vigorous sweeping and blowdowns with compressed air or steam.

Use of Compressed Air

Facilities generally prohibit using compressed air for cleaning. Exceptions apply only when cleaning inaccessible areas with no alternatives, following conditions in NFPA 652 Section 8.4.2.6.2 and NFPA 654 Section 8.2.2.4.

Before using compressed air:

-

Use vacuuming, sweeping, or water wash-down methods on accessible surfaces first.

-

Ensure post-cleaning dust accumulation does not exceed housekeeping thresholds.

Compressed air safety requirements:

-

Hoses must be equipped with pressure relief nozzles limited to 30 psi (207 kPa), per OSHA 29 CFR 1910.242(b).

-

Electrical equipment exposed to airborne dust must be rated for Class II, Division 2 (e.g., NEMA 12 or equivalent).

-

Remove or shut down ignition sources and hot surfaces before cleaning.

-

After blowdown, clean residual dust before reintroducing potential ignition sources.

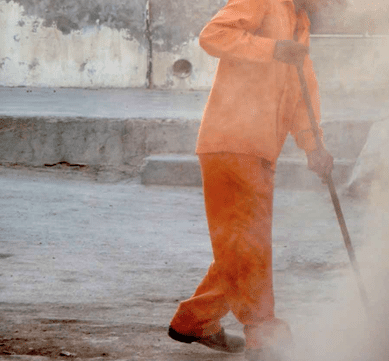

Personal Protective Equipment for Combustible Dust Cleaning

Flame-Resistant Garments

-

Provide flame-resistant clothing to all personnel exposed to combustible dust during cleaning or handling.

-

These garments minimize injury risks from dust ignition by reducing burn hazards.

-

Supplying proper flame-resistant clothing is essential for worker safety in dust-prone environments.

Selection Criteria for Flame-Resistant Garments

-

Consider thermal protective properties across a range of exposures.

-

Evaluate fabric quality, garment construction, and durability.

-

Ensure proper fit and design for safety and comfort.

-

Assess garment wear life and follow recommended laundering instructions.

-

Take wearer comfort and environmental conditions into account.

Care, Use, and Storage

-

Provide personnel with manufacturer instructions on garment care, use, maintenance, and limitations.

-

Educate workers about proper use of undergarments and overgarments.

-

Store garments inside, away from direct sunlight, in a dry, ventilated area, preferably on hangers.

-

Keep cleaned garments separate from uncleaned ones.

-

Follow manufacturer advice regarding storage conditions to prevent damage.

Additional Protective Equipment

-

Personnel handling dusty or granular materials should wear eye protection.

-

Where dust has more than nuisance toxicity, use tight-fitting or positive-pressure masks to ensure respiratory protection.

Training Requirements for Combustible Dust Cleaning Personnel

All operators, mechanics, and technical personnel should receive training on combustible dust hazards, including proper cleaning procedures and preventive measures for their specific operational areas.

-

New or returning employees: Those new to the facility or returning after six months or more must complete location-specific training emphasizing dust control and cleaning protocols.

-

Emergency procedures: Employees should be trained on responses to combustible dust incidents, including recognizing hazards, maintaining safety systems, and proper use of fire extinguishers. Gas-driven extinguishers should not be used on smoldering dust piles, as they can create explosive dust/air suspensions.

-

Cleaning equipment training: Personnel must learn proper use of combustible dust cleaning equipment and safe cleaning methods.

-

Refresher training: Conduct annual refreshers focusing on operational changes and reviewing emergency procedures rather than repeating onboarding content.

Effective training ensures personnel can prevent combustible dust accumulation, respond safely to incidents, and maintain compliance with industry standards.

Management Systems Supporting Combustible Dust Cleaning

Effective management systems are essential in combustible dust processing areas to minimize risk and ensure safe cleaning practices.

-

Management of Change (MoC): Any change to materials, raw material sources, process design, equipment, or dust-handling methods must follow the facility’s MoC program. This ensures that all potential hazards are assessed and mitigated before changes are implemented.

-

Permit to Work: Workers must obtain an approved permit before performing maintenance, cleaning, sanitation, or modifications on dust-handling equipment. The permit process includes reviewing work area rules, performing hazard checks, and inspecting the area after tasks are completed. Only after proper sign-off should equipment be returned to production.

Implementing structured management systems ensures that combustible dust cleaning programs remain effective, controlled, and compliant with safety standards.

Review and Continuous Improvement of Combustible Dust Cleaning Programs

A combustible dust cleaning program should be reviewed and updated at least every three years to maintain its effectiveness. Updates should also occur whenever specific circumstances arise, including:

-

After any dust-related incident, such as a fire, explosion, or near-miss.

-

When the Management of Change (MoC) process identifies operational or material changes.

-

Following significant modifications to the facility, processes, or equipment.

Regular reviews and timely updates ensure that the cleaning program remains effective, addresses emerging risks, and maintains compliance with safety standards.