What is Safety Data Sheet (SDS)?

Whether you’re manufacturing a chemical product or handling hazardous substances, a Safety Data Sheet (SDS) is essential. Formerly known as a Material Safety Data Sheet (MSDS), an SDS follows a standardized format. It communicates key details about hazards, safe handling, and emergency procedures.

An SDS ensures that workers and safety personnel have reliable information about hazardous materials. It also supports emergency responders with consistent guidance. SDSs are vital for regulatory compliance with OSHA and the Globally Harmonized System (GHS). They help prevent workplace incidents by clearly outlining risks and control measures. An up-to-date SDS is not just a requirement—it’s a key part of your safety plan.

In the following sections, we’ll explain the tests we offer. These services support the creation of a complete, compliant SDS.

Flammability Limits

Flammability limit testing determines the lower and upper concentration limits—known as the Lower Flammable Limit (LFL) and Upper Flammable Limit (UFL)—at which a chemical can ignite in air under specified conditions. This test is essential for volatile liquids and gases with sufficient vapor pressure to form combustible mixtures, such as refrigerants. The LFL represents the minimum concentration of a substance in air required for flame propagation, while the UFL is the maximum concentration at which ignition can still occur.

Knowing the flammability limits of a substance is vital for evaluating explosion risks and designing safe handling systems. These values guide decisions about ventilation requirements, safe storage, and operational conditions, especially in facilities managing volatile chemicals. LFL and UFL data are particularly useful during the development of new materials, in post-incident investigations, or when environmental or formulation changes could impact flammability. Testing ensures processes remain outside flammable concentration ranges, reducing the likelihood of ignition and enhancing workplace safety.

LFL and UFL are determined in a controlled lab setting by incrementally adjusting concentrations of the substance in air and observing flame propagation using an electrical ignition source. Once the LFL is established, UFL testing begins above a theoretical upper limit and is gradually adjusted until sustained ignition occurs. For refrigerants, tests follow ASHRAE 34 and ASTM E681, which define the methodology, ignition criteria, and required air moisture levels.

Boiling Point

Boiling point is the temperature at which the vapor pressure of a liquid equals the surrounding atmospheric pressure, allowing the liquid to convert to vapor through the formation of bubbles. This physical property is unique to each substance and serves as a fundamental parameter in identifying and characterizing chemical materials.

Understanding a substance’s boiling point is critical in several areas, including purity assessment, quality control, formulation design, and industrial process optimization. It helps identify unknown materials, detect the presence of impurities, and ensure consistency in production. When optimizing manufacturing conditions, knowing the boiling point guides temperature settings for reactions, separations, and distillation. Industries such as pharmaceuticals, chemical manufacturing, food processing, and environmental analysis all rely on boiling point data to maintain performance, efficiency, and safety in their processes.

Boiling point testing is also essential for meeting regulatory requirements. Certain safety, environmental, and transportation standards—such as those defined under OSHA, REACH, or GHS—require accurate boiling point data as part of chemical classification and hazard labeling.

Melting Point

The melting point is the temperature at which a solid turns into a liquid under standard atmospheric pressure. This transition point is a distinct physical property that helps identify and differentiate substances. For pure materials, the melting point is sharp and specific, while impurities often cause it to occur over a broader and lower temperature range.

Melting point testing plays a vital role in identifying hazardous materials and ensuring safe handling practices. Substances with low or variable melting points may pose storage or transportation challenges, especially if they become volatile or reactive at elevated temperatures. In flammable or thermally sensitive environments, knowing the melting point helps prevent thermal accidents, guides proper storage, and informs safe processing conditions. This data is crucial for industries such as pharmaceuticals, chemicals, and manufacturing, where material behavior under heat directly impacts product quality and operational safety.

Regulatory standards often require melting point data as part of chemical classification and safety assessments. Guidelines from agencies like OSHA, GHS, and REACH rely on melting point values to define proper labeling, hazard communication, and transport requirements.

Flash Point

Flash point is a critical property listed in Section 9 of a Safety Data Sheet (SDS), as it indicates the lowest temperature at which a liquid gives off enough vapor to ignite in air. This value helps classify the flammability of a substance and plays a key role in determining storage, handling, and transportation requirements. Accurately determining the flash point is essential for assessing fire and explosion risks, ensuring regulatory compliance, and protecting worker safety in environments where flammable liquids are used or stored.

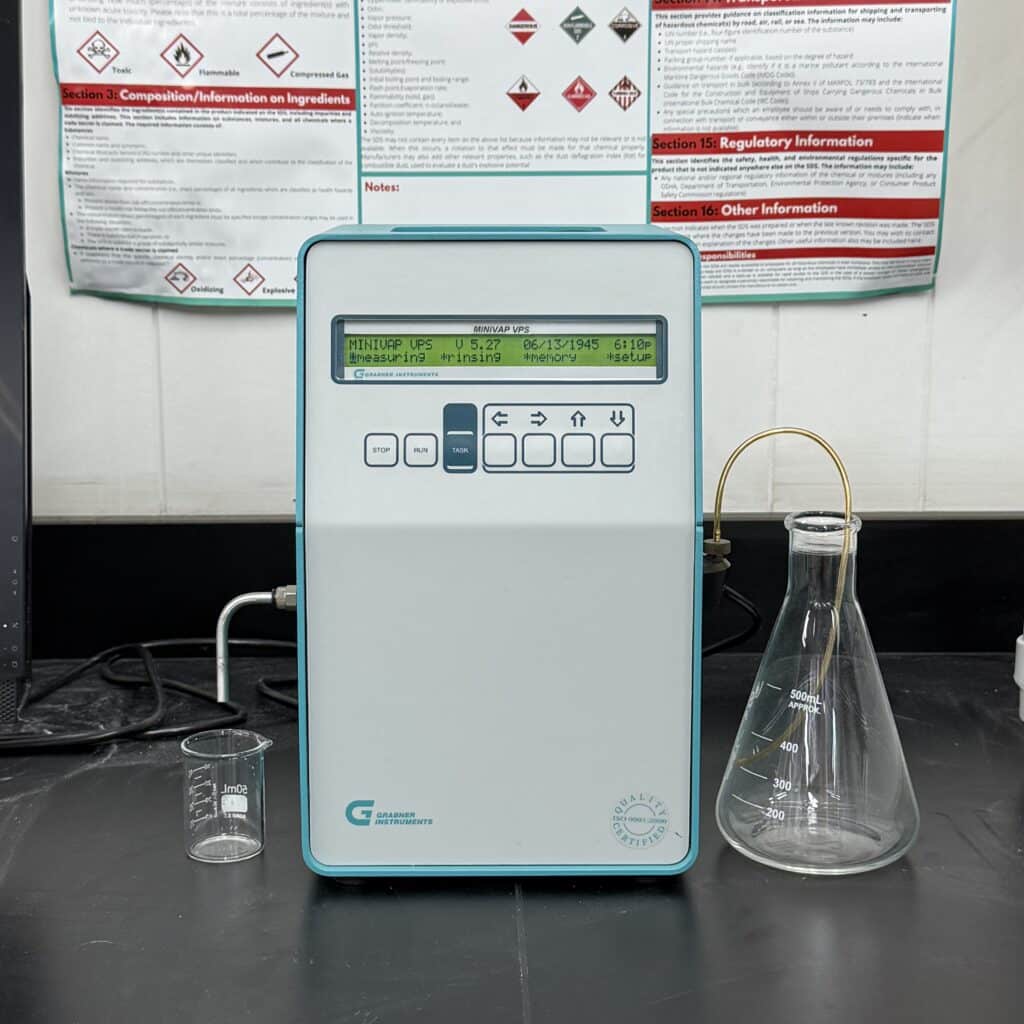

Vapor Pressure

Vapor pressure is the pressure exerted by a vapor in equilibrium with its liquid or solid phase at a given temperature. It indicates how readily a substance evaporates and is a key property for understanding volatility. As temperature increases, more molecules gain energy to escape the liquid or solid phase, resulting in higher vapor pressure.

Understanding vapor pressure is critical in applications involving volatile materials, especially in chemical manufacturing, petroleum refining, and environmental safety. Substances with high vapor pressure can pose significant risks, including flammability, toxic exposure, and pressure buildup in closed systems. Testing vapor pressure supports safer storage, handling, and transportation practices. It also informs process design, helps predict evaporation behavior, and ensures control over potential exposure in occupational settings. Regular testing is especially important when managing flammable or reactive compounds that are sensitive to temperature changes.

Vapor pressure data is often required by regulatory bodies to comply with safety, environmental, and transport standards. Agencies such as OSHA, the U.S. Department of Transportation (DOT), and international frameworks like GHS (Globally Harmonized System) use vapor pressure values to classify hazards, define safety labeling, and set handling protocols.

PH

pH is a measure of how acidic or alkaline a substance is, based on its hydrogen ion concentration. It is expressed on a scale from 0 to 14, with 7 representing a neutral state. Substances with a pH below 7 are acidic, while those above 7 are alkaline. Accurate pH testing is essential across industries for quality control, chemical compatibility, and process safety.

Monitoring pH is critical when handling chemicals that may be corrosive or reactive. It informs storage decisions, container compatibility, and the need for safety precautions such as personal protective equipment (PPE). Substances with extreme pH values can cause burns, equipment damage, or environmental harm if improperly managed. In chemical manufacturing, wastewater treatment, and emergency response situations, determining pH helps prevent accidents, ensures safe handling practices, and supports effective spill mitigation. It also plays a key role in reducing worker exposure and protecting the environment from harmful discharges.

Various regulatory bodies require pH measurement as part of safety and environmental compliance. Agencies such as the U.S. Environmental Protection Agency (EPA), Occupational Safety and Health Administration (OSHA), and Food and Drug Administration (FDA) have standards that incorporate pH data to evaluate chemical hazards and environmental discharge limits. Safety Data Sheets (SDS) typically include pH values to guide safe usage and handling.

Relative Density

Relative density, also referred to as specific gravity, is the ratio of the density of a substance to the density of a reference substance—typically water at 4°C or 20°C. It is a dimensionless value used to determine whether a substance is heavier or lighter than the reference material. Relative density is commonly applied in industries such as pharmaceuticals, petroleum, construction, and food and beverage manufacturing to support product formulation, material identification, and quality control.

Understanding the relative density of a substance plays a key role in safe handling, storage, and transportation. Substances with a higher density than water may sink and cause environmental damage if spilled into waterways, while those with lower density may float and spread differently. This knowledge helps determine appropriate containers, packaging, and segregation practices. Relative density is also critical for assessing the compatibility of chemicals for mixing and for identifying unknown materials, supporting proper labeling, storage planning, and emergency response strategies.

Relative density is a required parameter in many safety and regulatory frameworks. It is included in Safety Data Sheets (SDS) as part of the physical and chemical properties of substances. Agencies such as OSHA and the U.S. Department of Transportation (DOT) use specific gravity data to classify hazardous materials and define proper handling and shipping procedures.

Apparent Bulk Density

Apparent bulk density is the mass of a bulk material divided by its total volume, including voids. It is usually expressed in grams per cubic centimeter. This value shows how powders or particles pack and behave under different conditions. The test involves filling a known volume with the material and measuring its mass. Particle shape and size affect bulk density. Fine or irregular particles often pack more tightly and have higher densities. This property is important in many fields, including pharmaceuticals, agriculture, construction, and chemical manufacturing.

Apparent bulk density affects how materials flow, pack, and behave in storage and transport. It helps determine suitable containers and prevents overfilling or collapse. It also helps reduce dust buildup or clogging in machines. Bulk density influences flowability, which affects dosing, production speed, and equipment function. In safety-critical settings, this measurement helps prevent static discharge and manage airborne particles. It can reduce the risk of fire or explosion when handling combustible powders.

Many industries require bulk density data in safety and quality documents. It appears in technical data sheets and industry standards. Organizations like ASTM and ISO reference it in their handling and transport guidelines. Examples include ASTM D7481 and ASTM B212.

Dust Explosibility (Kst, MEC, MIE, etc.)

The Dust Explosion Severity Test evaluates how violently a combustible dust cloud can explode under specific conditions. It focuses on three key parameters: the maximum explosion pressure (Pmax), the maximum rate of pressure rise ((dP/dt)max), and the deflagration index (Kst). Kst reflects how quickly pressure builds during an explosion, while Pmax indicates the highest pressure the explosion can generate. These values help determine the severity of a potential dust explosion and classify the dust into explosion classes: St-1, St-2, or St-3.

Understanding explosion severity is vital for industries handling combustible dust. A dust explosion can lead to catastrophic equipment damage, facility loss, or injury. By identifying how severe an explosion could be, facilities can design effective explosion protection systems—such as venting, suppression, and containment—according to standards like NFPA 68 and ISO 6184. The severity data also plays a key role in regulatory compliance, safety planning, and adapting to material or process changes.

The test is performed according to American Standard Testing Method (ASTM) E1226 and BS EN 14034 Parts 1 & 2.

Viscosity

Viscosity describes a liquid’s resistance to flow and plays an important role in how a substance behaves during processing, transfer, and storage. In safety assessments, viscosity can affect spill behavior, mixing efficiency, and atomization, all of which influence flammability and exposure risks. Accurate viscosity data supports proper handling procedures and helps ensure the safe design of equipment and processes for hazardous or reactive liquids.

Autoignition

Autoignition temperature is the lowest temperature at which a substance ignites on its own, without a spark or flame. This property is important for safety and is listed in Section 9 of a Safety Data Sheet (SDS). It helps assess fire and explosion risks. Knowing this temperature guides safe operating, storage, and handling practices, especially in high-heat environments with flammable materials.

Decomposition Temperature

Decomposition temperature is the temperature at which a chemical starts to break down into simpler substances, often releasing heat or gases. Knowing this temperature is crucial for identifying thermal hazards such as fire, explosion, or toxic gas release. Understanding the decomposition temperature helps ensure safer storage, handling, and processing by avoiding conditions that could trigger dangerous decomposition reactions.

Liquid Conductivity

Liquid conductivity measures a liquid’s ability to conduct electric current, which is especially important for assessing static electricity risks during handling and storage. Because liquids with low conductivity can accumulate static charges, they increase the chance of sparks that may ignite flammable vapors or dust. Therefore, understanding a liquid’s conductivity helps implement proper grounding and bonding practices. As a result, this reduces electrostatic hazards and ensures safe operation in industrial environments.

Conclusion

A complete, compliant Safety Data Sheet (SDS) starts with accurate, high-quality data—and that’s exactly what Prime Process Safety Center delivers. From fundamental properties like boiling point, vapor pressure, and pH, to advanced testing such as flammability limits and dust explosibility (Kst, MEC, MIE), our laboratory services are designed to support your chemical safety strategy from the ground up. Whether you’re developing a new product, navigating regulatory requirements, or optimizing existing processes, we provide the testing you need to stay safe, compliant, and competitive.

Ready to build your SDS with confidence? Contact Prime Process Safety Center today to speak with our experts or request a custom quote tailored to your material testing needs.