We also offer

What Is a Dust Hazard Analysis (DHA)

A Dust Hazard Analysis (DHA) is a formal, systematic, and facility-specific engineering evaluation performed to identify, assess, and manage fire, flash fire, and explosion hazards associated with combustible dusts. A DHA evaluates where combustible dust is present, how it may be generated, accumulated, or dispersed into an ignitable suspension, potential ignition sources, and whether existing prevention and protection measures are adequate to control the risk.

A properly conducted DHA examines process operations, materials, equipment, building features, and operating conditions unique to a facility. This includes dust generation points, material handling and transfer systems, ventilation and dust collection systems, housekeeping practices, and ignition source controls, along with an evaluation of safeguards such as explosion venting, isolation, suppression, and fire protection systems to support compliance with applicable fire codes, safety regulations, and industry consensus standards.

Why do I Need a Dust Hazard Analysis

Combustible dust presents a significant fire and explosion hazard in industrial environments where fine particulate solids are manufactured, processed, handled, or stored. Industries such as food processing, chemical manufacturing, woodworking, metalworking, pharmaceuticals, plastics, energy production, and recycling routinely generate dusts that can ignite or explode when specific conditions are present.

History has demonstrated that uncontrolled combustible dust hazards can result in serious injuries, fatalities, extensive property damage, business interruption, and regulatory enforcement actions. Dust-related incidents frequently occur in facilities where dust accumulation, ignition sources, and confinement exist during normal operations.

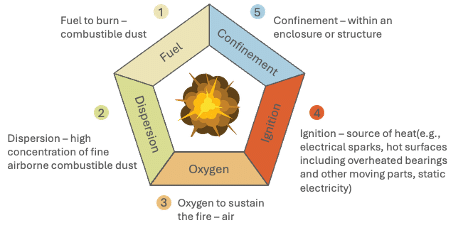

Dust fires and explosions occur when the necessary elements are present: combustible dust, oxygen, dispersion, confinement, and an ignition source. A combustible dust combined with oxygen and an ignition source can result in a fire. When the airborne dust suspended to form a cloud with concentration exceeding its minimum explosible concentration and is confined within equipment, ducts, or buildings, a deflagration or explosion may occur.

Routine housekeeping and general safety practices alone are not sufficient to manage combustible dust hazards. Effective risk management requires a structured and technically defensible evaluation of where dust is generated, how it behaves within processes and equipment, and whether existing safeguards are adequate. A Dust Hazard Analysis provides this systematic approach by identifying hazards, evaluating current controls, and supporting targeted actions to reduce risk.

Dust Hazard Analysis Compliance and Regulations

Combustible dust hazards are a major focus of industry standards, fire codes, and regulatory enforcement due to the severity of potential consequences. Facilities that handle, process, or manufactures combustible dust are expected to formally identify and manage these hazards through a documented Dust Hazard Analysis.

NFPA Standards

-

NFPA 660 – Standard for Combustible Dusts

The consolidated NFPA standard addressing combustible dust hazards across industries. It establishes requirements for Dust Hazard Analysis, ignition control, fire prevention, and explosion protection, providing a comprehensive framework for consistent and technically sound hazard management.

- NFPA 652 – Standard on the Fundamentals of Combustible Dust

Requires facilities that manufacture, process, blend, convey, repackage, or handle combustible dust to complete a Dust Hazard Analysis. NFPA 652 establishes the DHA framework and directs users to applicable industry-specific standards. -

Industry-Specific NFPA Standards

NFPA 654, 61, 484, 655, and 664 address combustible dust hazards in general manufacturing, food processing, metal dusts, sulfur handling, and woodworking operations. - NFPA 68 and NFPA 69

Provide requirements for explosion protection through deflagration venting, suppression, isolation, and prevention systems. - NFPA 499

Addresses classification of combustible dusts and hazardous locations for electrical installations.

OSHA Guidance

-

Combustible Dust National Emphasis Program (CPL 03‑00‑008)

Directs OSHA inspections toward facilities that generate, handle, or store combustible dust. OSHA commonly references NFPA standards as recognized industry practices when evaluating hazard identification, risk mitigation, and housekeeping. Facilities lacking a documented DHA or adequate controls may be subject to citations.

-

OSHA General Duty Clause (Section 5(a)(1))

Requires employers to identify and mitigate recognized hazards, including combustible dust, when feasible. Even in the absence of a specific OSHA standard, employers may be cited if combustible dust hazards are not adequately addressed. A documented DHA serves as strong evidence of due diligence.

Conducting a Dust Hazard Analysis helps facilities demonstrate compliance with NFPA standards, reduce regulatory exposure, and establish a defensible basis for hazard identification and control.

When Do I Need a Dust Hazard Analysis

A Dust Hazard Analysis should be performed whenever there is a potential for combustible dust to be generated, accumulate, or become airborne within a facility.

Typical scenarios include:

- Facility design or new equipment installation

New construction, processes, or equipment involving dust-producing materials should be evaluated before startup. - Process changes or material substitutions

Changes to operations, production rates, or raw materials can significantly alter dust hazards and require DHA review or update. - Periodic revalidation

DHAs should be reviewed and updated periodically or whenever operational changes affect dust accumulation, ventilation, or ignition control. - Following dust-related incidents or near misses

Fires, flash fires, explosions, or near-miss events indicate the need to reassess hazards and safeguards. - Regulatory, AHJ, or insurance requirements

Fire authorities, insurers, or corporate safety programs may require a current DHA to demonstrate compliance and risk management.

A proactive DHA helps facilities identify hazards early, verify existing safeguards, and implement effective mitigation strategies to maintain safe and compliant operations.

Who Can Perform Dust Hazard Analysis

A Dust Hazard Analysis should be performed by qualified personnel with specialized knowledge of combustible dust hazards and experience in industrial safety and process operations. Effective DHAs require an understanding of dust explosibility characteristics, equipment design, ignition sources, and applicable codes and standards.

Qualified DHA performers may include:

- Internal safety or engineering teams

Personnel with appropriate training and experience in combustible dust hazards and process safety. - Independent dust hazard analysis consultants

Specialists who provide objective, technically defensible evaluations, particularly for complex or high-risk operations. - Laboratory and testing professionals

Experts who generate combustible dust test data to support hazard evaluation and mitigation decisions.

Engaging qualified professionals ensures that hazards are properly identified, risks are accurately evaluated, and recommendations are practical, defensible, and aligned with industry standards.

How Our Dust Hazard Analysis Services Can Help You

At Prime Process Safety Center, our Dust Hazard Analysis services help facilities identify, evaluate, and manage combustible dust hazards while supporting compliance with recognized safety standards.

Our DHA services include:

- Regulatory alignment with NFPA 660, NFPA 652, and OSHA guidance

- Qualified subject-matter experts in combustible dust and process safety

- Comprehensive facility assessments of process equipment, buildings, and dust-handling operations

- Actionable, risk-based recommendations for housekeeping, engineering controls, and explosion protection

- Testing support through our in-house laboratory

- Implementation support and training for long-term risk management

- Clear, defensible documentation suitable for AHJs, insurers, and audits

Our structured approach ensures combustible dust risks are effectively managed, personnel are protected, and compliance obligations are met.

Why Choose Prime Process Safety Center

Prime Process Safety Center provides technical excellence, regulatory insight, and practical solutions for managing combustible dust hazards.

What sets us apart:

- Extensive industry experience across food, pharmaceuticals, woodworking, metals, chemicals, energy, and recycling

- Facility-specific, customized solutions rather than generic templates

- Proactive risk management focused on incident prevention

- Clear, audit-ready reporting that supports inspections and insurance reviews

- Training and ongoing support to sustain compliance and safety performance

- Cost-effective recommendations that balance safety and operational efficiency

Choosing Prime Process Safety Center means partnering with experts dedicated to helping your facility operate safely, compliantly, and confidently.

FAQ

1. What is Dust Hazard Analysis (DHA)?

DHA is a systematic review to identify and evaluate the potential fire, explosion, and flash fire hazards associated with the presence of combustible dust in an industrial facility.

2. Why is DHA important in process safety?

DHA is critical because combustible dust can pose severe fire and explosion hazards. Conducting a DHA helps in identifying these risks and implementing measures to mitigate them, ensuring workplace safety.

3. What are the key elements of a DHA?

A DHA typically includes identifying combustible dust hazards, evaluating the likelihood of a dust explosion, examining existing safety measures, and recommending additional safety controls.

4. What does the Dust Hazard Analysis involve?

A dust hazard analysis is a systematic review to identify potential hazards, evaluate existing safeguards, and recommend additional safeguards or process improvements to reduce combustible dust explosion or fire hazards. NFPA 652 does not specify a particular format, but common elements of the DHA generally include material characterization, process characterization, evaluation of existing safeguards, mitigation recommendations and verification. A DHA is the best way to protect people and facilities from the dangers of a combustible dust explosion and reduce legal liability.

5. What is the focus of Dust Hazard Analysis and NFPA 652 Regulations?

A Dust Hazard analysis requires that a hazard must be present – this is usually the presence of an explosible atmosphere and an effective source of ignition. The key requirements for complying with NFPA 652 regulations revolve around the completion of a thorough Dust Hazard Analysis. We aim to provide a coherent focus for the control and mitigation strategies for controlling combustible dust fire and explosion risk.

6. How often should a DHA be conducted?

OSHA recommends conducting a DHA every five years or when a change in process or equipment could alter the dust explosion risk.

7. How to conduct a Dust Hazard Analysis?

Conducting a Dust Hazard Analysis involves a systematic approach to identify and mitigate specific combustible dust hazards. For every identified hazard, it is essential to establish safe operating ranges and outline existing hazard management measures. The primary objective of conducting a Dust Hazard Analysis is to meticulously pinpoint all potential hazards within your facility, particularly those that might have been previously unrecognized. This could be achieved by

- Identifying dust fire and explosion hazards;

- Assessing risk of dust fire and explosion by evaluating the ignition likelihood and consequence of dust fire and explosion.

- Recommending effective and practical hazard and risk control measures;

- Providing the supporting services to assist you in implementing changes and safety measures to prevent dust explosions and fires;

- Providing performance-based analyses in case the physical conditions prevent effective implementations of some safety measures/solutions;

- Tackling both dust fire and dust explosion hazards hand-in-hand.

8. What are common sources of combustible dust in facilities?

Common sources include wood dust, metal powders, certain food ingredients, plastics, textiles, and some chemical residues.

9. What industries typically require a DHA?

Industries that handle powders and bulk solids, like food processing, pharmaceuticals, woodworking, metal processing, and chemicals, typically require a DHA due to the potential presence of combustible dust.

10. How can facilities control dust hazards?

Control measures include implementing effective housekeeping practices to minimize dust accumulation, using proper dust collection systems, and designing equipment to minimize dust escape and prevent ignition sources.

11. How does a DHA integrate with overall process safety management?

DHA is an integral part of Process Safety Management (PSM). It aligns with PSM elements like hazard identification, risk management, employee training, and emergency response planning.

12. When is a Dust Hazard Analysis required for my facility?

NFPA 652, “Standard on the Fundamentals of Combustible Dust,” requires that all facilities handling or producing combustible dust complete a Dust Hazard Analysis or DHA. While NFPA standards are not enforceable, the Occupational Health and Safety Administration (OSHA) relies on these standards when conducting enforcement activities under the Combustible Dust National Emphasis Program. In addition, compliance with NFPA 652 may be required under state and local fire codes, which are typically structured around NFPA 1, “Fire Code,” and/or the International Fire Code.

13. Who should perform a DHA?

A DHA should be performed by qualified personnel or consultants with expertise in dust hazard assessment and knowledge of applicable regulations and industry standards.

14. What are the consequences of not conducting a DHA?

Failing to conduct a DHA can result in increased risk of dust explosions, regulatory non-compliance, potential legal liabilities, and increased insurance costs.

For more detailed answers, please visit Most Frequently Asked Questions about Dust Hazard Analysis page, or simply contact us.