Introduction

Combustible dust hazards continue to pose serious fire and explosion risks across many industries, from food processing and woodworking to metals, chemicals, and pharmaceuticals. For years, facilities managing these hazards have had to navigate multiple NFPA standards, often applying both general requirements and industry-specific rules at the same time. This fragmented approach made compliance more complex and, in some cases, harder to manage consistently.

To address this challenge, the National Fire Protection Association introduced NFPA 660, Standard for Combustible Dusts and Particulate Solids. Effective December 6, 2024, NFPA 660 consolidates NFPA 652 and five industry-specific combustible dust standards into a single, unified document. The goal is to simplify compliance, improve clarity, and strengthen how facilities identify, evaluate, and control combustible dust hazards.

In this guide, we break down what NFPA 660 is, how it differs from previous standards, and what facilities need to know to stay compliant. Whether you are updating an existing dust hazard analysis or preparing for future inspections, understanding NFPA 660 is an important step toward safer operations and more defensible combustible dust management.

What Is NFPA 660?

NFPA 660, Standard for Combustible Dusts and Particulate Solids, is the consolidated NFPA standard that governs the identification, evaluation, and control of combustible dust hazards across all industries. It brings together the fundamental requirements and industry-specific guidance that were previously spread across multiple NFPA documents into a single, coordinated standard.

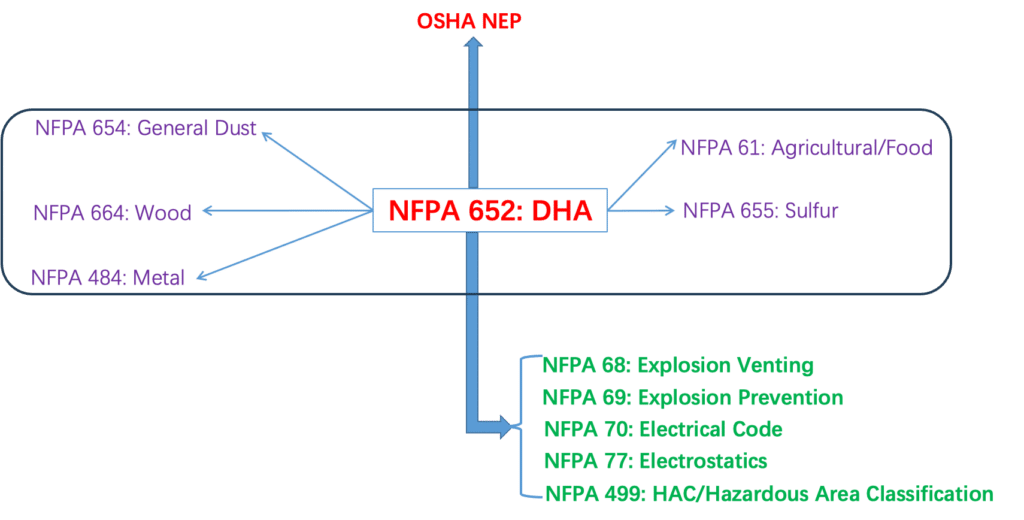

Before NFPA 660, facilities were required to comply with NFPA 652 for general combustible dust requirements, while also following additional standards based on their industry or material type. These included:

- NFPA 61 – Agricultural and food processing facilities

- NFPA 484 – Combustible metals

- NFPA 654 – Combustible particulate solids (general industry)

- NFPA 655 – Sulfur fires and explosions

- NFPA 664 – Wood processing and woodworking facilities

NFPA 660 integrates the technical requirements from these standards into one document, reducing overlap and improving consistency in how combustible dust hazards are addressed. Rather than referencing multiple standards, facilities can now use NFPA 660 as the primary framework for combustible dust safety.

It is important to note that NFPA 660 does not replace all dust-related NFPA standards. Key documents such as NFPA 68(Explosion Protection by Deflagration Venting), NFPA 69 (Explosion Prevention Systems), and NFPA 499 (Hazardous Area Classification) remain separate and are still referenced when applicable.

Overall, NFPA 660 is intended to make combustible dust requirements easier to understand and apply, while maintaining the same level of technical rigor. For facility owners and safety managers, it provides a clearer path for conducting Dust Hazard Analyses (DHAs), implementing controls, and demonstrating compliance during inspections and audits.

How Is NFPA 660 Different from NFPA 652 and Other Standards?

NFPA 660 builds on the foundation established by NFPA 652, the general standard for combustible dust, but goes further by consolidating multiple industry-specific standards into a single, unified document. While NFPA 652 focused primarily on the fundamental principles of dust hazard management, such as performing Dust Hazard Analyses (DHAs), controlling ignition sources, and establishing safety programs, NFPA 660 provides both these core requirements and detailed guidance for specific industries.

Key differences include:

- Unified Structure: Instead of navigating NFPA 652 alongside separate standards like NFPA 61 (food), NFPA 484 (metals), or NFPA 664 (woodworking), NFPA 660 integrates all industry-specific requirements into one document. This simplifies compliance and reduces the risk of conflicting guidance.

- Expanded DHA Guidance: NFPA 660 centralizes and clarifies Dust Hazard Analysis requirements, including who can perform them, how often they should be updated, and the documentation expected.

- Industry-Specific Detail: NFPA 660 includes dedicated chapters for agriculture, metals, sulfur, wood, and “other” combustible dusts, offering more targeted recommendations than NFPA 652 alone.

- New Requirements: NFPA 660 introduces updates for operational readiness, housekeeping, spark detection, flame-resistant garments, and explosion protection system design—enhancements that were previously scattered across multiple standards.

- Improved Clarity and Consistency: Terms, definitions, and testing requirements are standardized across all dust types, helping prevent misinterpretation and ensuring everyone in an organization interprets the standard in the same way.

In short, NFPA 660 streamlines combustible dust compliance, making it easier for facilities to follow a single, cohesive standard that addresses both fundamental safety practices and the specific risks of their industry. For facility managers, this means less confusion, more consistent hazard control, and a clearer path to regulatory compliance.

How NFPA 660 Is Organized

NFPA 660 is organized to make combustible dust requirements easier to find, understand, and apply across different industries. Instead of separating general rules and industry-specific standards into multiple documents, NFPA 660 brings everything together in a single, logical structure.

The standard is divided into three main parts:

Fundamentals (Chapters 1–10)

These chapters apply to all facilities that handle or generate combustible dust, regardless of industry. They establish the core requirements for dust hazard management, including:

-

Scope, purpose, and applicability

-

Definitions and terminology

-

Dust hazard analysis (DHA) requirements

-

Management systems, training, and documentation

-

Housekeeping and fugitive dust control

-

Fire, flash fire, and explosion protection concepts

This section forms the baseline for combustible dust safety and must be followed by every facility covered by NFPA 660.

Industry-Specific Chapters (Chapters 21–25)

These chapters provide additional requirements tailored to specific materials or industries where combustible dust hazards are common. Each chapter builds on the fundamental requirements and adds controls relevant to that sector:

-

Chapter 21: Agricultural and food processing operations

-

Chapter 22: Combustible metals

-

Chapter 23: Sulfur handling and processing

-

Chapter 24: Wood processing and woodworking facilities

-

Chapter 25: Combustible dusts and particulate solids not otherwise specified

Facilities typically use the fundamentals together with the applicable industry chapter, rather than choosing one or the other.

Annexes (A–Z)

The annexes provide non-mandatory but highly valuable guidance to help interpret and apply the requirements in the main chapters. They include explanatory material, examples, calculation methods, and recommended practices. While not enforceable, the annexes are often referenced during DHAs, design decisions, and compliance reviews.

This organization allows facilities to quickly identify what applies to everyone, what applies to their specific industry, and how to implement the requirements effectively, making NFPA 660 far more user-friendly than the previous multi-standard approach.

Key Changes and New Requirements in NFPA 660

Although NFPA 660 consolidates existing combustible dust standards, it also introduces several important updates that affect how facilities manage dust hazards.

Unified Dust Hazard Analysis (DHA) Requirements

NFPA 660 centralizes DHA requirements into a single framework applicable across industries. Facilities handling combustible dust must continue to conduct DHAs and revalidate them at least every five years, or sooner when processes, materials, or equipment change.

Clearer Expectations for DHA Qualifications

The standard clarifies that DHAs must be conducted by qualified individuals with demonstrated knowledge of combustible dust hazards, applicable NFPA standards, and facility operations. This improves consistency and strengthens the defensibility of DHA results.

Expanded Evaluation of Reactivity Hazards

Beyond deflagration risks, NFPA 660 places greater emphasis on hazards such as self-heating, thermal instability, and water reactivity, particularly for reactive materials and metal dusts.

Stronger Management and Documentation Requirements

NFPA 660 reinforces the need for formal dust hazard management programs, including documented procedures for training, inspections, maintenance, housekeeping, and corrective actions. Combustible dust safety is treated as an ongoing process, not a one-time assessment.

Clarified Housekeeping and Fugitive Dust Control

The standard provides clearer guidance on dust accumulation thresholds and promotes risk-based housekeeping programs that address fugitive dust throughout the facility.

Interim Safeguards When Full Compliance Is Delayed

When immediate compliance is not feasible, NFPA 660 requires interim measures to reduce risk while permanent solutions are developed.

Overall, NFPA 660 strengthens combustible dust safety by improving clarity, consistency, and accountability across industries while reinforcing the importance of continuous hazard management.

Industry-Specific Applications

NFPA 660 applies across a wide range of industries and includes additional requirements for certain materials and operations. In addition to the general combustible dust provisions, the standard contains industry-focused requirements for:

-

Agricultural and food processing operations, including grain handling and food manufacturing where combustible dust is generated during conveying, milling, and storage

-

Combustible metal processing, such as aluminum, magnesium, and other reactive metals involved in machining, grinding, or additive manufacturing

-

Sulfur handling and processing, with requirements addressing fire prevention, storage, and explosion risk

-

Wood processing and woodworking facilities, including sawmills and furniture manufacturing where wood dust accumulation is a primary hazard

-

Other industries handling combustible particulate solids, including chemical, pharmaceutical, plastics, and specialty material operations not covered by a dedicated industry chapter

Facilities must apply both the general requirements of NFPA 660 and any applicable industry-specific provisions based on the materials and processes present.

How to Stay Compliant with NFPA 660

Maintaining compliance with NFPA 660 requires a structured approach to identifying hazards, implementing controls, and keeping documentation current. Key steps include:

-

Conduct a Dust Hazard Analysis (DHA) to identify combustible dust hazards, evaluate explosion and fire risks, and determine required safeguards

-

Implement engineering and administrative controls based on DHA findings, including dust collection, explosion protection, and safe operating procedures

-

Establish effective housekeeping programs to limit dust accumulation in accordance with NFPA thresholds

-

Verify material explosibility through testing, where dust characteristics are unknown or process conditions have changed

-

Train employees on combustible dust hazards, safe work practices, and emergency response procedures

-

Maintain documentation and review compliance regularly, updating the DHA when processes, materials, or equipment change

NFPA 660 compliance is not a one-time effort. Ongoing evaluation and periodic review are necessary to ensure safeguards remain effective as operations evolve.

Conclusion

NFPA 660 marks a major step forward in combustible dust safety, consolidating multiple standards into a single, clear framework. By understanding its structure, key changes, and industry-specific requirements, facility managers can simplify compliance and strengthen dust hazard management.

Proactively aligning your operations with NFPA 660 helps reduce fire and explosion risks, protects personnel, and supports regulatory compliance. Facilities that stay current with the standard—through regular Dust Hazard Analyses, proper housekeeping, and effective risk controls—can ensure safer, more efficient operations while avoiding costly incidents or enforcement actions.