What is Reactive Chemical Testing?

Reactive chemical testing is a vital aspect of process safety in industrial operations where energetic or unstable substances are present. This testing involves evaluating how chemicals respond to heat, pressure, or mixing with other materials—conditions that can lead to hazardous reactions if not properly understood. Through controlled laboratory analysis, companies can identify potential thermal and pressure-related risks before they escalate into dangerous incidents.

Understanding chemical reactivity is essential for preventing accidents, designing effective emergency relief systems, and ensuring regulatory compliance. It provides the data needed to make informed decisions about handling, storage, and process design—ultimately protecting both people and infrastructure.

In this blog, we’re exploring the main approaches to reactive chemical testing, highlighting the techniques and instruments our lab uses to uncover critical safety insights.

Differential Scanning Calorimeter (DSC)

Differential Scanning Calorimetry (DSC) is a thermal analysis technique that measures heat flow in a sample during heating or cooling. It reveals key thermal events such as melting, crystallization, phase transitions, and decomposition. In reactive chemical testing, DSC evaluates thermal stability and reactivity by detecting exothermic and endothermic behaviors. The method compares heat flow between a sample and a reference under the same temperature program. This produces a thermal profile that shows how the material behaves during heating or cooling cycles.

DSC plays a vital role in process safety. It identifies potential thermal hazards and evaluates the compatibility and stability of chemical substances. Engineers use DSC to screen materials for decomposition, detect unwanted reactions, and generate kinetic data for safety models. For example, heat release above 800 J·g⁻¹ may indicate explosive potential. Comparing profiles in air versus nitrogen helps distinguish oxidation from decomposition. DSC provides key data like onset temperatures, reaction heats, and kinetic parameters. This supports safer process design, better material selection, and effective relief system development. Understanding a material’s thermal behavior allows for better risk mitigation and operational decisions.

The applicable testing standard is ASTM E537 – the Standard Test Method for the Thermal Stability of Chemicals by DSC. For high accuracy, experts should interpret DSC results and may use additional methods like adiabatic calorimetry.

Differential Thermal Analysis (DTA)

Differential Thermal Analysis (DTA) is a valuable analytical technique used in process safety to evaluate the thermal behavior of materials. By monitoring the temperature difference between a sample and an inert reference material during controlled heating, DTA can detect exothermic and endothermic events, providing insight into phase transitions, decomposition reactions, and thermal stability. Common equipment used for DTA testing in safety assessments includes the Carius tube and the Rapid Screening Device (RSD), both of which allow simultaneous pressure monitoring—critical for detecting gas evolution or runaway reactions.

The importance of DTA lies in its ability to identify potentially hazardous thermal behaviors before they pose risks in real-world processes. It enables early detection of exothermic decomposition, phase instability, and gas generation, which are vital in preventing thermal runaway and equipment failure. DTA is semi-quantitative but highly effective for screening reactive or unstable substances. It offers valuable insights such as onset temperatures (with safety margins), qualitative reaction intensities, vapor-liquid equilibrium data, and total gas output. These findings help process engineers assess compatibility, design safer systems, and implement effective mitigation measures.

Although no single universal standard governs all DTA applications, the method aligns with general thermal analysis practices referenced in safety guidelines such as ASTM E537 (which focuses on DSC, but its principles often guide thermal safety testing) and company-specific safety protocols.

Thermogravimetric Analysis (TGA)

Thermogravimetric Analysis (TGA) is a key thermal technique that measures a sample’s weight change during controlled heating. Performed in inert or reactive atmospheres, TGA reveals a material’s composition, thermal stability, and behavior across temperature ranges. Engineers use TGA to measure moisture content, detect volatile components, and analyze decomposition patterns. It also helps assess oxidative stability. By tracking mass change over time or temperature, TGA provides critical data on thermal properties and safety concerns.

In process safety, TGA helps evaluate thermal degradation, mass loss, and gas evolution risks. Specifically, it identifies safe operating temperatures and detects the onset of decomposition. Additionally, TGA reveals incompatibilities between materials and process conditions. Engineers use this data to determine temperature ranges where hazardous reactions may occur. These include exothermic decomposition or the release of flammable or toxic gases. As a result, TGA insights support safer process design, better material selection, and stronger mitigation strategies. Ultimately, this reduces the risks of thermal incidents, equipment failure, or environmental release.

ASTM standards ensure accurate and consistent TGA results. For example, ASTM E1131 guides composition analysis, while ASTM E1641 covers decomposition kinetics. Furthermore, ASTM E1582 and E2040 address instrument calibration. Additional standards—such as ASTM E2550 (thermal stability), ASTM E2105 (TGA/IR), and ASTM E1868 (loss-on-drying)—support more specialized testing applications.

Accelerating Rate Calorimeter (ARC)

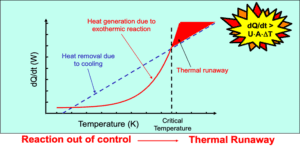

The Accelerating Rate Calorimeter (ARC) is essential for evaluating the thermal stability and runaway potential of chemicals. It simulates worst-case scenarios where no heat escapes the system. ARC testing identifies the onset of exothermic decomposition and tracks temperature and pressure rise rates. The instrument runs in heat-wait-search (HWS) mode. It gradually heats the sample, monitors for self-heating, and switches to adiabatic mode when the reaction starts. ARC tests can take time, but they effectively detect slow self-heating reactions. These reactions may trigger dangerous thermal events in industrial processes.

ARC testing provides critical insights for chemical process safety. It quantifies self-heating rates, pressure buildup, and exothermic onset temperatures. Based on this data, engineers can predict key safety metrics. These include time to maximum rate (TMR), temperature of no return (TNR), and self-accelerating decomposition temperature (SADT). In turn, these values help define safe operating limits and guide the selection of containment or relief systems. Moreover, ARC results are especially important for substances with autocatalytic reactions or delayed exotherms. Therefore, they support safe scale-up, process optimization, and proactive hazard mitigation.

ARC testing follows ASTM E1981 – the Standard Guide for Assessing Thermal Stability by Accelerating Rate Calorimetry.

Reaction Calorimetry

Reaction calorimetry is a powerful tool for measuring the heat generated or absorbed during chemical reactions. It reveals the energetics and thermodynamics of chemical processes in real time. Researchers use this method to study reaction pathways and assess process conditions. Reaction calorimeters replicate features of stirred tank reactors, including dosing, mixing, and temperature control. This setup simulates real plant conditions while capturing thermal changes throughout the reaction.

In process safety, reaction calorimetry is especially important. It helps identify exothermic hazards, runaway potential, and stability concerns. The method provides data on heat flow and energy output. It also tracks unreacted material and physical changes like gas evolution. This information supports scale-up, reactor design, and process control strategies. Chemical engineers use it to reduce risk and ensure safe operations in both batch and continuous systems.

There is no single global standard for reaction calorimetry. However, industry guidance documents offer widely accepted practices. These include CCPS Guidelines for Chemical Reactivity Evaluation and relevant Good Laboratory Practices. ASTM E1981 also provides general thermal analysis principles. Reaction calorimetry often complements other hazard assessment methods. It helps support regulatory compliance and process safety documentation.

Vent Sizing Package (VSP)

The Vent Sizing Package (VSP), developed during the DIERS project in the 1980s, is a vital tool in process safety for designing emergency relief systems. By simulating runaway reactions under adiabatic conditions with low thermal inertia, the VSP enables accurate prediction of temperature and pressure behaviors that would occur in industrial-scale vessels. Its design includes a thin-walled metal test cell enclosed in a pressurized autoclave, allowing the system to closely mimic real-world process conditions. Through controlled experiments, the VSP collects essential thermal and pressure data, enabling detailed analysis of reaction kinetics, gas generation rates, and flow regimes during overpressure events.

Performing VSP tests is critical for ensuring the safe operation and design of emergency relief systems. These tests help identify the maximum expected rates of temperature and pressure rise during a runaway event, enabling accurate determination of relief device capacity and vessel containment requirements. The VSP can differentiate between foamy and non-foamy systems, assess the impact of viscosity, and support the design of both top- and bottom-vented systems. Ultimately, it provides process safety engineers with the data needed to prevent overpressure scenarios, minimize the risk of explosions, and protect equipment and personnel.

The use of the VSP aligns with several industry codes and best practices. Standards such as API 520 and API 521 guide the design and sizing of pressure relief systems, especially in the petrochemical and chemical processing sectors. The VSP also supports compliance with DIERS technology guidelines by generating data under true adiabatic conditions—ensuring reliability and consistency in emergency relief design. Applicable across industries including pharmaceuticals, energy, and food processing, VSP testing offers a standardized and scientifically validated method for managing pressure relief and ensuring regulatory compliance.

Conclusion

Reactive chemical testing is a cornerstone of process safety, providing essential insights into how substances behave under thermal and pressure stresses. Techniques such as Differential Scanning Calorimetry (DSC), Differential Thermal Analysis (DTA), Thermogravimetric Analysis (TGA), Accelerating Rate Calorimetry (ARC), Reaction Calorimetry, and Vent Sizing Package (VSP) testing each contribute unique, critical data to help industries prevent accidents, optimize processes, and comply with safety regulations. By understanding the thermal stability, decomposition risks, and pressure dynamics of materials, companies can design safer operations, emergency relief systems, and mitigate costly or catastrophic incidents.

At Prime Process Safety Center, we specialize in delivering comprehensive reactive chemical testing services using state-of-the-art instruments and proven methodologies. Our expert team works closely with clients to provide precise analysis, thorough interpretation, and actionable recommendations tailored to your specific process needs. Whether you require detailed hazard assessments, kinetic modeling, or relief system design support, we are committed to helping you safeguard your personnel, assets, and environment.

Contact us today to learn how our expertise and advanced testing solutions can enhance your process safety management and ensure regulatory compliance.